As the printing and packaging industry accelerates into the era of smart manufacturing, MK celebrates its 30th anniversary and makes a strong appearance at CHINAPRINT 2025, bringing a wonderful appearance. After three decades of relentless innovation, MK took the stage at CHINAPRINT 2025 with a bold vision for the intelligent future of print and packaging — unleashing disruptive power and lighting the path toward smart manufacturing as a fearless pioneer.

"MK's 30 years of technological refinement is not only a celebration of a milestone, but also a revolution in leading smart packaging."

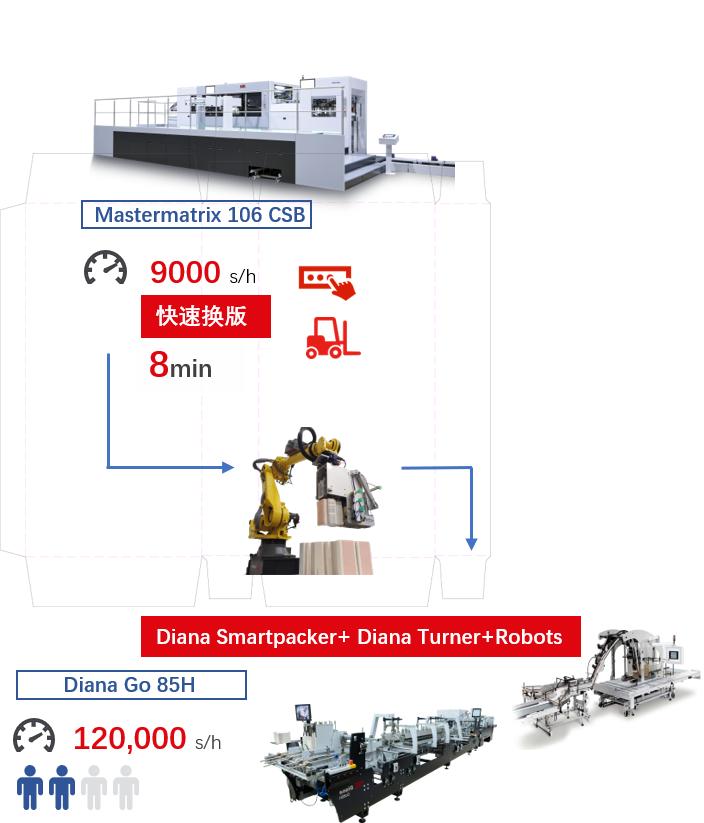

At the Print Expo, the MK booth attracted much attention for a full-process automated production line with an integrated AGV solution, which attracted many exhibitors to stop. From finished product outbound to die-cutting, box gluing, boxing, and finished product inbound, the entire production process is seamlessly connected, redefining the boundaries of production efficiency.

Through digital twin technology, the status of each order and the progress of every machine are reflected in real time, creating a digital mirror of the factory floor and ushering in a new era of truly smart manufacturing.

During the demonstration, the MasterMatrix 106CSB achieved a record-breaking 6-minute ultra-fast plate change, demonstrating the amazing production process on site and showing MK's commitment to speed and precision.

In today's packaging factories, the biggest cost is not high-end printing machines or rising labor costs, but the hidden "breakpoints" in the production process. These invisible inefficiencies are quietly consuming profits, reducing productivity and hindering growth.

At the CHINAPRINT 2025 exhibition, MK launched four innovative products designed to break through these bottlenecks:

MK3920FFCSB

Three-unit die-cutting with stripping&blanking and hot stamping machine, flexible modular design, three-unit technology can be freely combined, excellent texture and ultra-high efficiency

MK1060CB

Fully die-cutting with stripping&blanking machine, optimized for double-knife platemaking, no underutilized stripping unit, reducing equipment investment and maximizing material utilization. Suitable for pharmaceutical packaging and multi-specification items, as well as medicine boxes, paper cups, instant noodles, etc.

MK920DVF

Requires no plate making, with one device and one varnish achieving 'partial varnish + three-dimensional thick coating + digital hot stamping'.

MK and KURZ signed a cooperation agreement and reached a strategic partnership. This cooperation covers multiple fields such as digital hot stamping, hot stamping and cold stamping technology, jointly promoting technological progress and market expansion, and deep value chain integration to enable smarter, more environmentally friendly and more responsive hot stamping application systems.

This year marks the 30th anniversary of MK. In the past 30 years of ups and downs, MK has always put customer needs first. Since its establishment, MK has won the deep trust and long-term trust of customers by providing high-quality products, reliable services and customized innovative solutions. At the CHINAPRINT 2025 exhibition, customers were enthusiastic and the first-day order volume broke the record, which confirmed the customers' trust and support for MK as always.

We will continue to be committed to exquisite craftsmanship, intelligent transformation and sustainable development, injecting new impetus into the future of the global printing and packaging industry.

We look forward to hearing from you. In order to respond to your message more quickly, we need some information. *These are required