Tianjin Jointelligent Technology Co., Ltd., founded in 2016, is a smart factory total solution supplier. As a leader in the field, Jointelligent concentrates on R&D and innovation, combining advanced technology and creative thinking to provide specialized solutions to satisfy the needs of various industries.

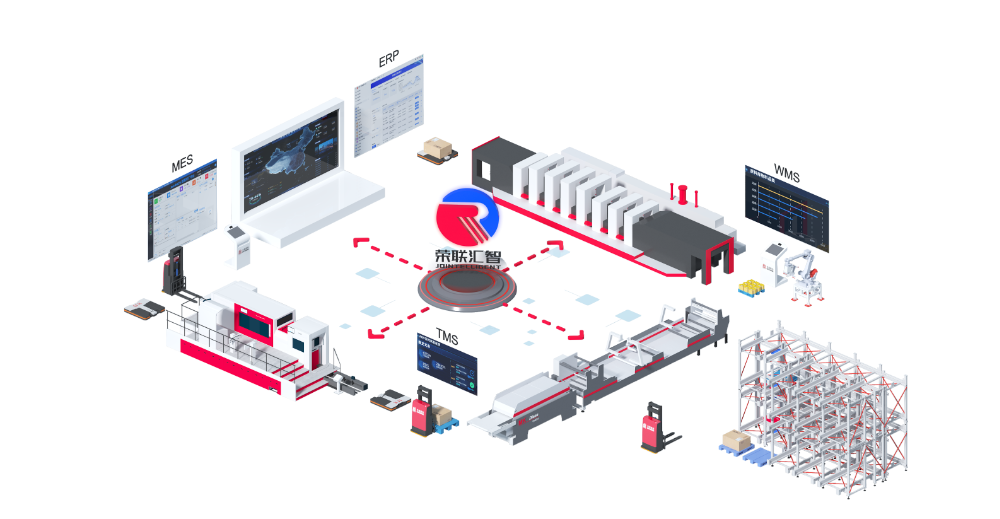

Jointelligent has been engaged in intelligent manufacturing for many years, with project cases covering many famous enterprise groups and listed companies in the industry. The main business includes smart warehouse construction, autonomous mobile robots (AGV), enterprise resource planning (ERP), manufacturing execution systems (MES), data collection systems (MDIS), warehouse management systems (WMS), digital identity management systems (DIM), advanced planning and scheduling (APS), logistics automation systems (LAM), MK Cloud systems, intelligent hardware equipment transformation, non-standard software customization services, and other solutions. MK Cloud, intelligent hardware equipment transformation, non-standard customized software services, and other solutions.

The company adheres to the business philosophy of integrity, focus, excellence, innovation, and win-win and continuously provides customers with high-quality products and professional services.

Based on the process flow and market demand, we should rationally plan the functional zoning layout and simultaneously implement environmental protection and energy optimization schemes

• Factory Layout Planning :Plan factory functional areas based on production processes and logistics.

• Capacity Planning:Create a capacity plan aligning with market needs and business strategy.

• Energy Utilization Planning:Optimize the energy structure,improve energy utilization efficiency, and reduce production costs.

• Environmental Protection Planning:Consider factory's environmental impact and devise protection measures.

Digital backbone for real-time production monitoring, empowering smart manufacturing decision-making

• Worker management

• Equipment management

• Material management

• Process method

• Circumstance awareness

• Detection control

Our solution is specifically designed for the printing industry, capable of reaching deep into the production process to directly interface with equipment, enabling fully automated logistics across all processes and procedures. One AGV can replace approximately 2-3 workers, providing swift responses while effectively eliminating production losses caused by material handling errors.

• Medium-sized warehouses, logistics centers, and freight yards;

• Suitable for warehouses under 24 meters in height with irregular layouts;

• Compatible with multiple material storage methods;

• Offers good equipment redundancy, low operation and maintenance costs, and ease of maintenance;

• Features a simple and versatile design with a broad range of applications;

• Ideal for materials in large quantities but with limited varieties.

• Suitable for large warehouses, logistics centers and freight yards;

• Applicable to warehouses with a height of 24 meters or above and regular shapes;

• Suitable for the storage of most materials;

• High degree of automation, fast picking speed, and high space utilization;

• Optimal for multi-variety and small-batch applications.

We look forward to hearing from you. In order to respond to your message more quickly, we need some information. *These are required