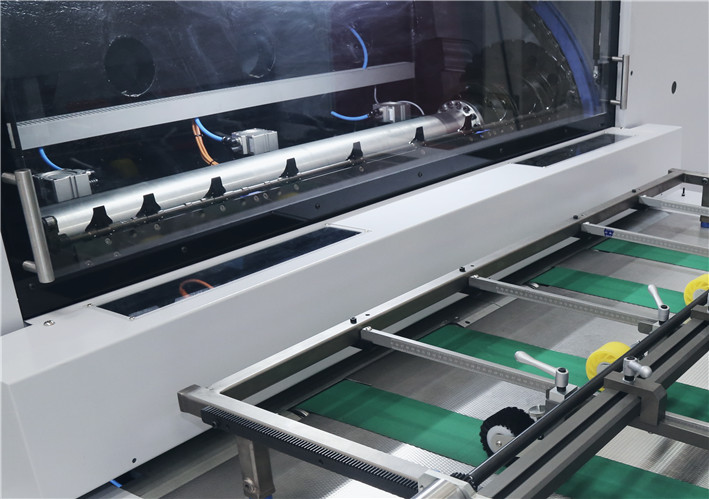

Non-stop Feeder

Automatic non-stop (optional)

Feeder logistics (optional)

Motorized suction head adjustment

Motorized adjustment of lateral guides

Mechanical double-sheet control

Feeder Table

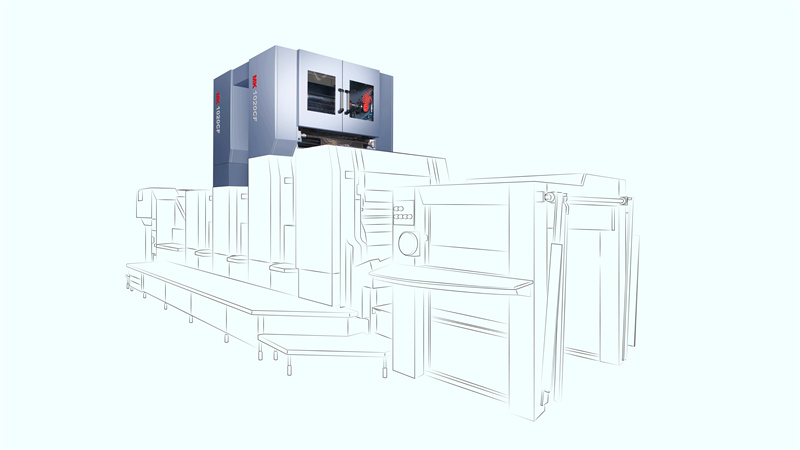

MasterSet optical sheet alignment system

Central adjustment of the rollers and brushes

Ultrasonic double-sheet control

MasterSet(optional)

Use high-speed, high-precision image sensors to directly detect color marks, printing patterns, or paper edges, digitally position paper, and improve paper positioning accuracy and product quality

Adopt servo system to achieve high-precision registration of paper to paper. Large amount of automatic deviation correction and wide adaptability, which brings lower downtime rate of paper feeding

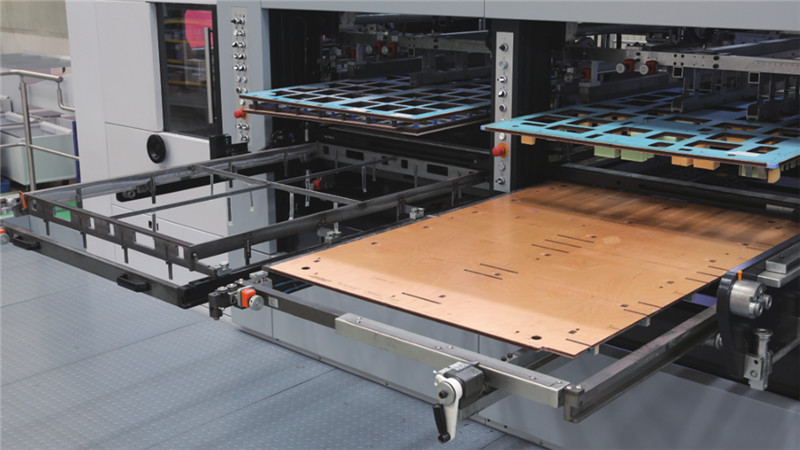

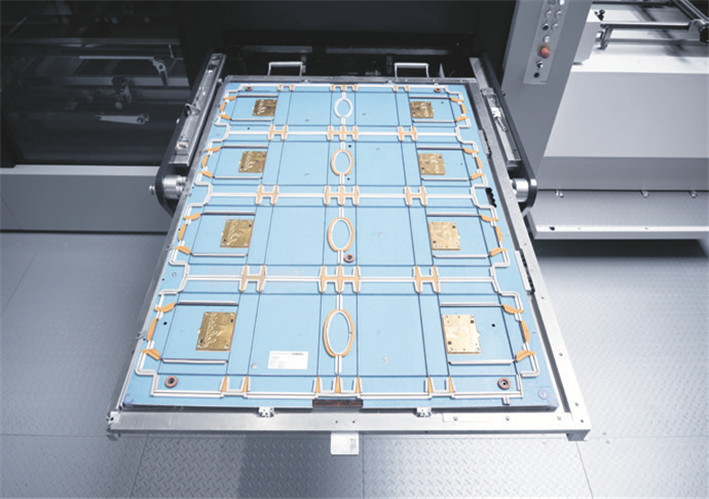

Die-cutting Station

Register system

Motorized die-cutting pressure adjustment

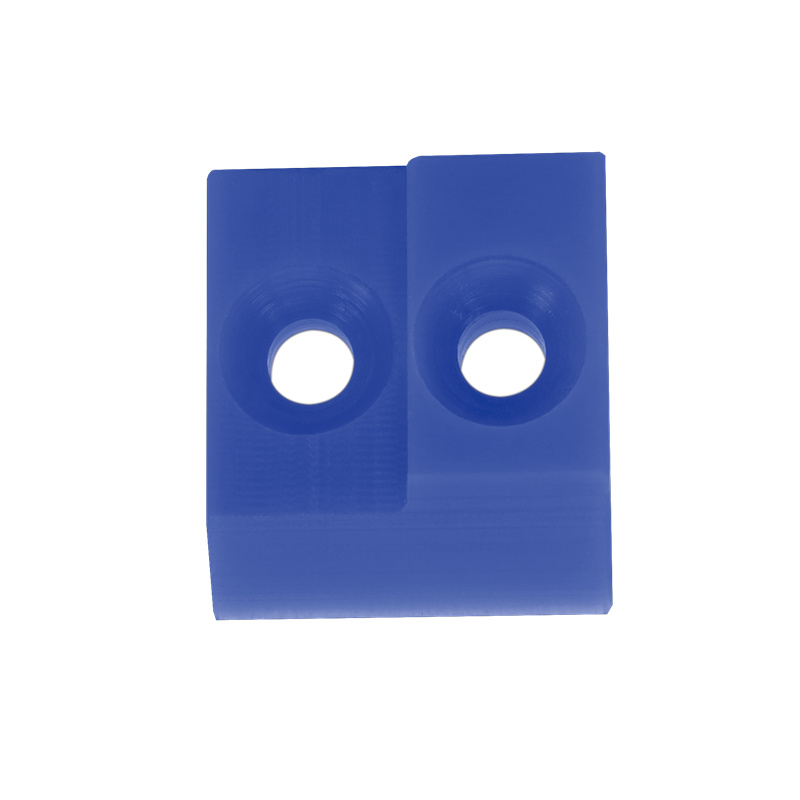

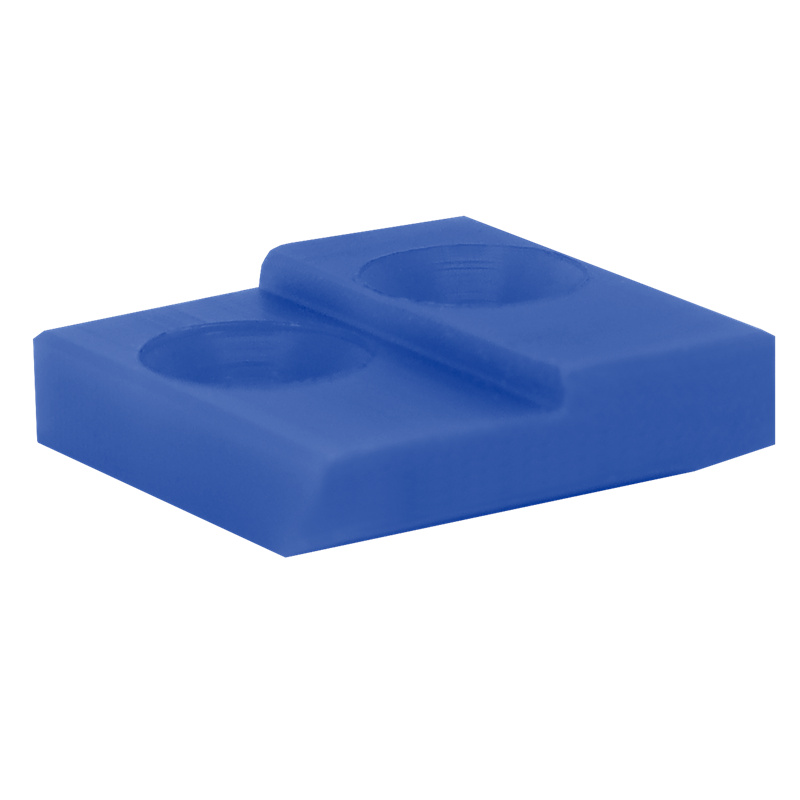

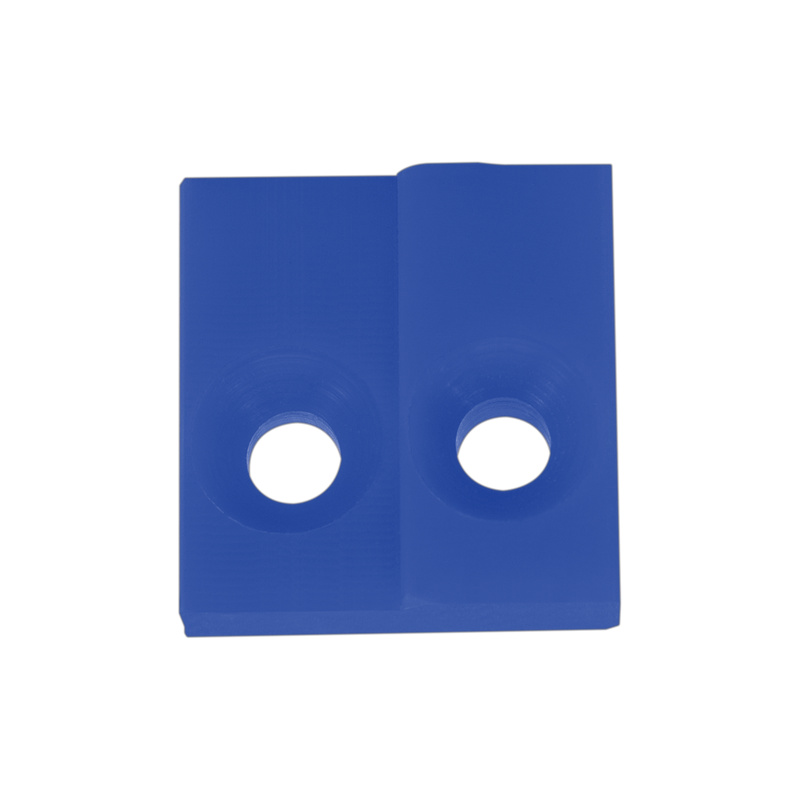

Pneumatic locking and unlocking of chase and cutting plate

Cutting plate fine adjustment

Air cushion for easy cutting plate handling

Quick-lock chase

Chase changer (optional)

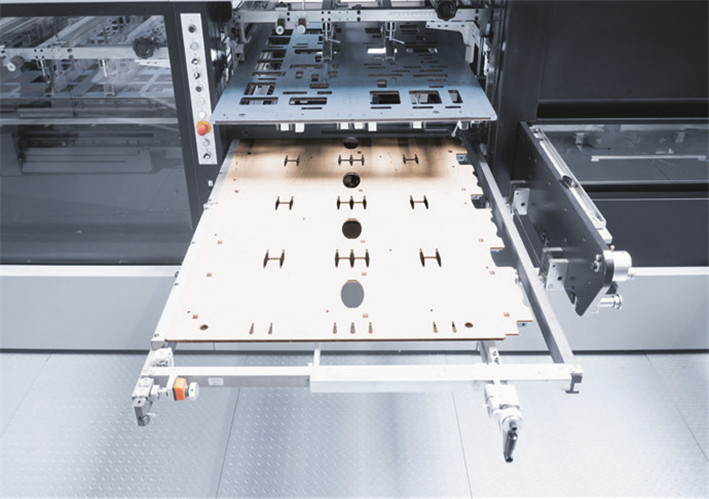

Stripping Station

Integrated quick-lock systems for all tools

Tool fine adjustment with position indicators

Test sheet removal

Vacuum device

Pneumatic opening and closing of the window

Preparation table (optional)

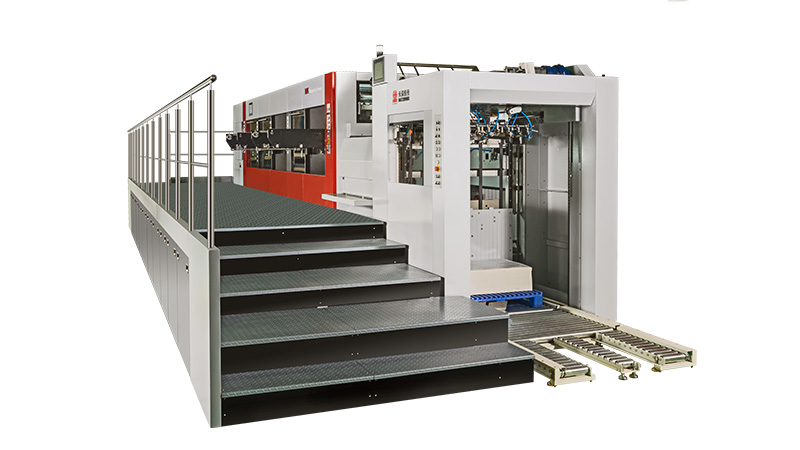

Blanking Station

Integrated quick-lock systems for the top tool

Automatic non-stop and pallet change system

Tie sheet inserter

Vacuum device

Pneumatic opening and closing of the window

Second touchscreen (optional)

Sample Sheet Removal

Sample sheet removal during production, completely interruption-free

Sheet is cut, stripped and then made available

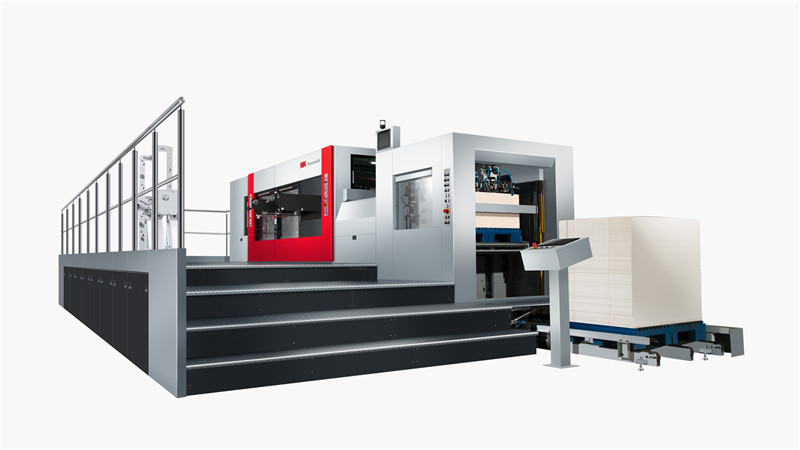

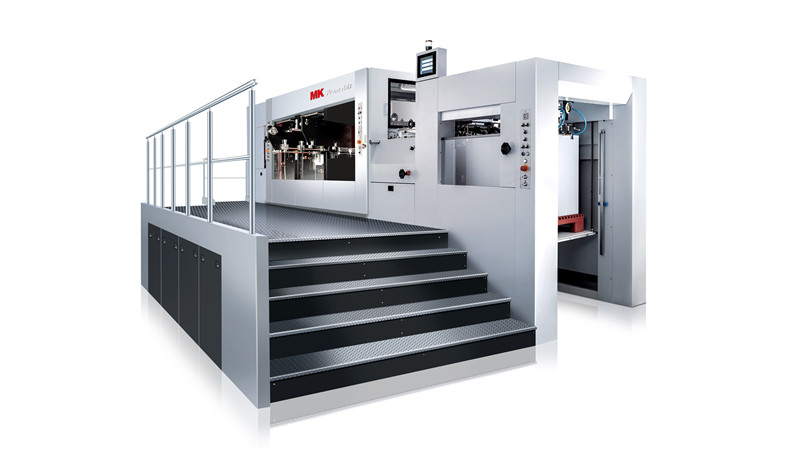

| Processable materials | Promatrix 145 CSB |

| Paper (min.) | 90g/m2 |

| Solid cardboard (max.) | 2,000 g/m2 |

| Corrugated cardboard (max.)/with MasterSet | 4.0mm/2.0 mm (0.16/0.08 in) |

| Performance data | |

| Sheet format (max.)/with MasterSet | 1 ,060x1 ,450 mm (41.73x 57.09 in) |

| Sheet format (min.) | 450 x 580 mm (17.72x22.83in) |

| Die-cutting pressure (max.) | 5.5 MN/550t |

| Machine speed (max.) | 7 ,000 sheets per hour. |

| Pile heights (incl. pallet) | |

| Feeder pile height (max.): | 1,800 mm (70.87in) |

| without non-stop | 1,600 mm (62.99in) |

| in non-stop operation | 2,500kg |

| Feeder pile weight (max.): | 2,000kg |

| Delivery pile height (max.) | 1,500 mm (59.06in) |

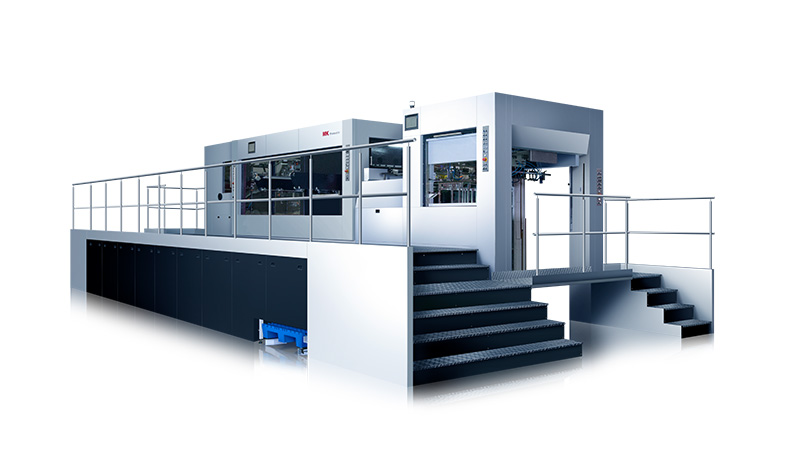

| Machine dimensions | |

| Machine length (approx.) | 12.9m (507.87 in) |

| Machine width (approx.) | 7.6m (299.21 in) |

| Machine height (approx.) | 3.3m (129.92in) |

For more information, please download the PDF brochure, or click "Contact" to subscribe

Click download

Related Products

Question consultation message

We provide complete product solutions, product manuals and more wonderful contents. Please leave your message and information below