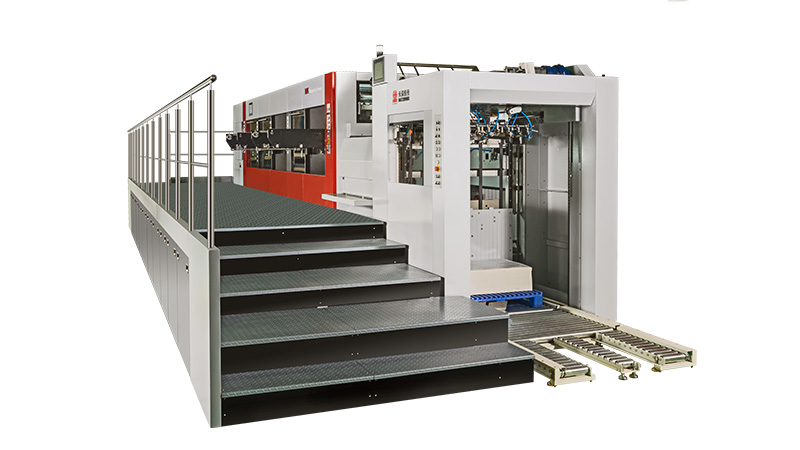

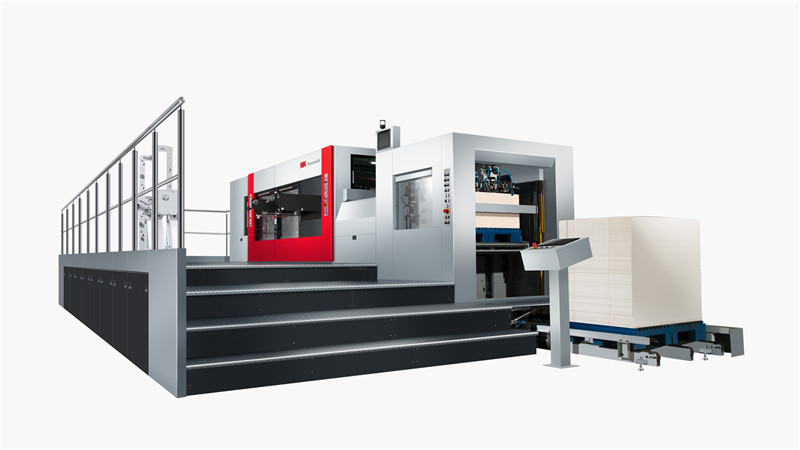

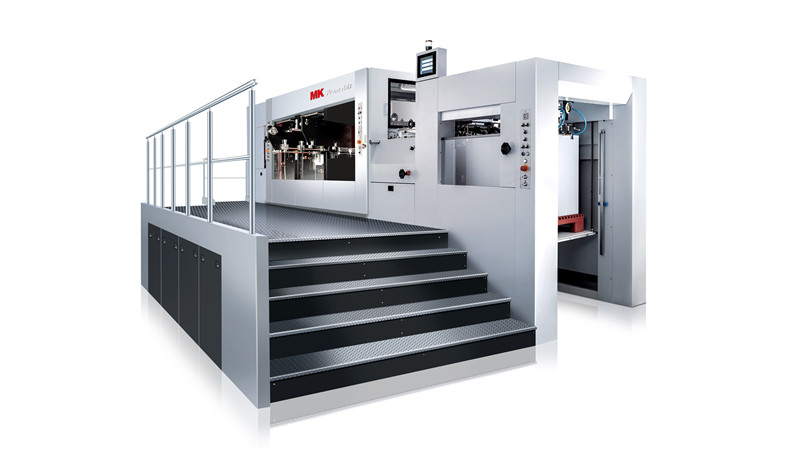

Non-stop Feeder

Suction head for paper, cardboard and corrugated cardboard

Suction head with quickpositioning function

Pile platform with motorized pile side alignment

Mechanical doublesheet control

Feed Table

MasterSet optical sheet alignment system (optional)

Central adjustment of the rollers and brushes

Suction belt table

Ultrasonic doublesheet control

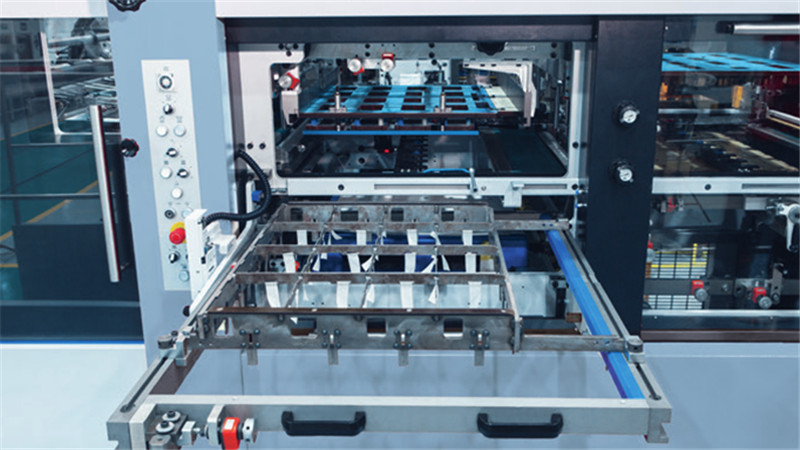

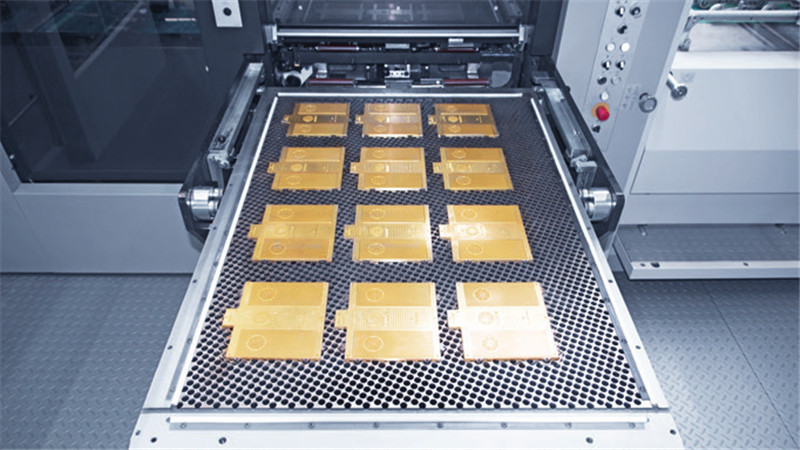

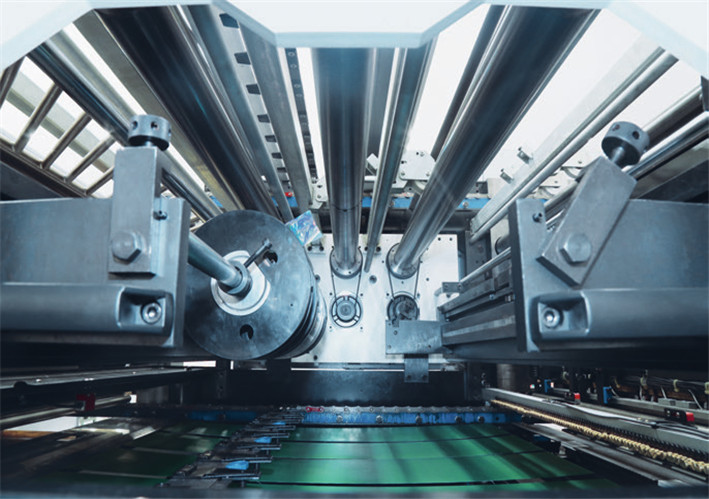

Hot Foil Stamping

Foil guiding longitudinal and transversal

Brush system for foil dispose

Foil advancing program for optimal foil saving

20 heating zones

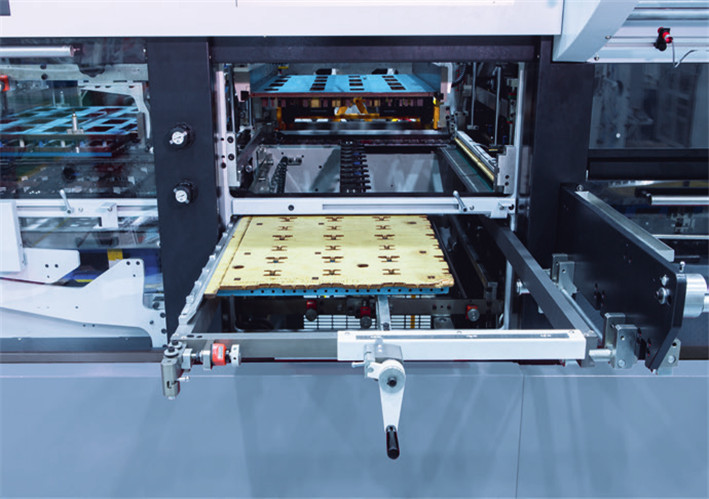

Stripping Station

Integrated quicklock systems for all tools

Tool fine adjustment with position indicators

Test sheet removal

Preparation table (optional)

Simple conversion to hotfoil handling

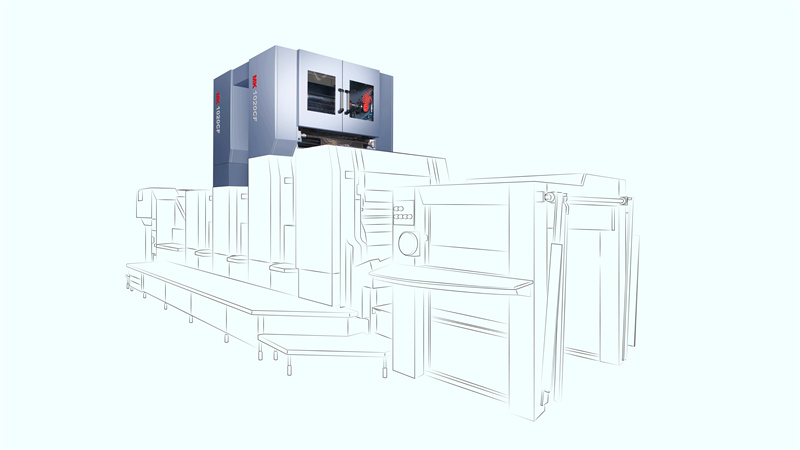

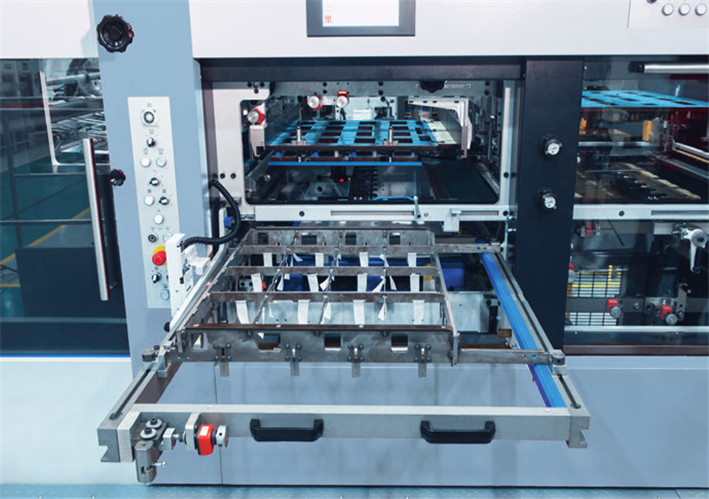

Blanking Station

Integrated quicklock system for the top tool

Automatic nonstop and pallet change system

Tie sheet inserter

Vacuum device

Second touchscreen

Sample sheet removal during production

| Processable materials | Duopress 106 FCS/FCSB |

| Paper (min.) | 90 g/m2 |

| Solid cardboard (max.) | 2,000 g/m2 |

| Corrugated cardboard (max.)/with MasterSet | 4.0 mm/2.0 mm (0.16/0.08 in) |

| Performance data | |

| Sheet format (max.) | 760 x 1,060 mm (29.92 x 41.73 in) |

| Sheet format (min.) | 350 x 400mm (13.78 x 15.75 in) |

| Die cutting pressure (max.) | 2.5 MN/250t |

| Machine speed (max.) | 6,000 sheets per hour |

| Performance data hot-foil embossing | |

| Hotfoil embossing speed (max.) | 5,000 sheets per hour |

| Temperature | 40°C- 180°C |

| Number of heating zones | 20 |

| Foil feeding shafts (per station) | 3 longitudinal, 2 transversal |

| Foil reel diameter (longitudinal): | 250 mm (9.84 in) |

| Foil reel diameter (transversal): | 200 mm (7.87 in) |

| Foil width | 20-1,060 mm (0.79-41.73 in) |

For more information, please download the PDF brochure, or click "Contact" to subscribe

Click download

Related Products

Question consultation message

We provide complete product solutions, product manuals and more wonderful contents. Please leave your message and information below