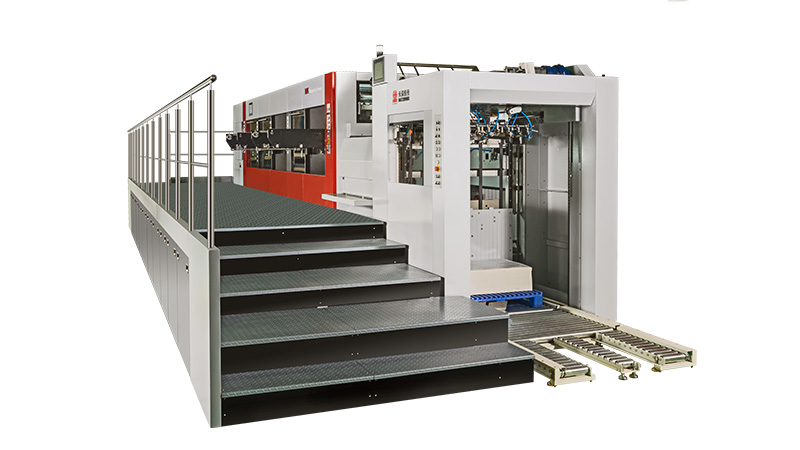

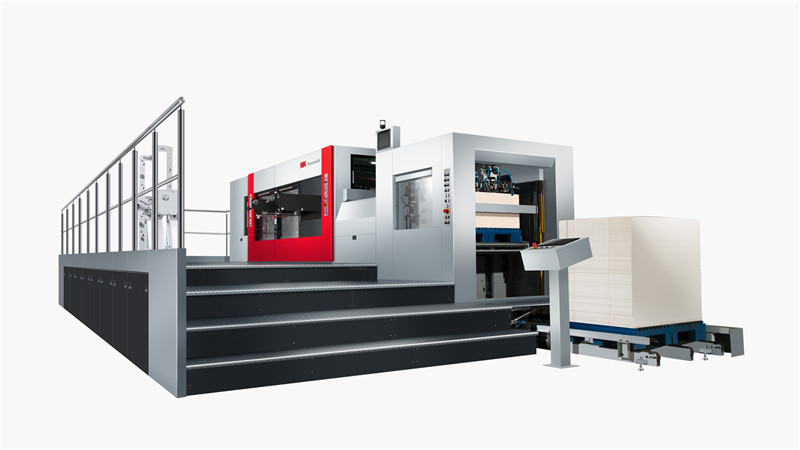

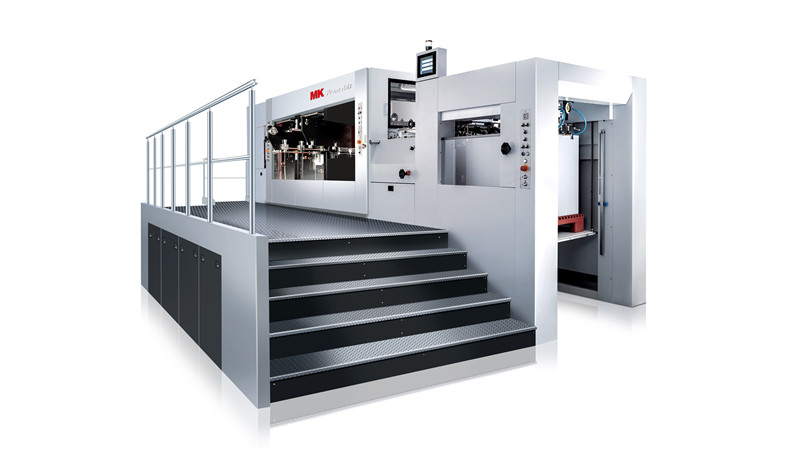

Feeding Section

The paper feeding section is driven and controlled by a servo motor

The motorized side blower can be moved flexibly.

Paper pile automatic correction

The motorized adjusted feeder head makes operation easily.

Ultrasonic double sheet detector

The third-generation mechanical double-sheet detection device

Paper pressing roller frame can be adjusted as a whole

Servo drive main & auxiliary feeding

MasterSet

Suitable for European standard 1200x800mm pallet

Master Feeder(Optional, used with feeder logistic)

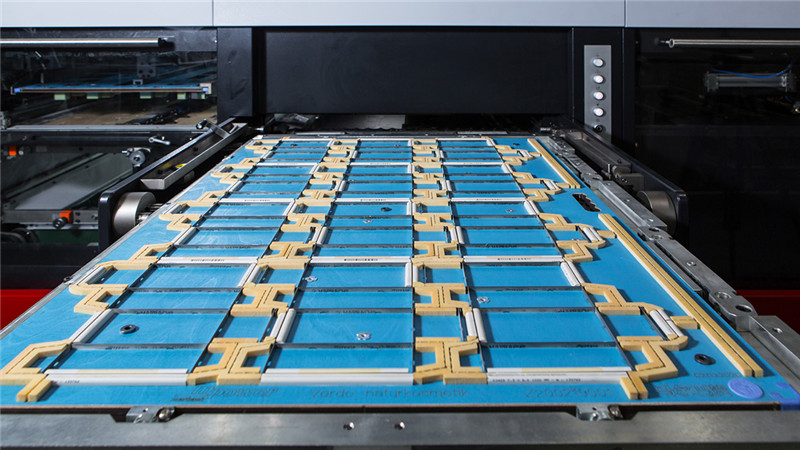

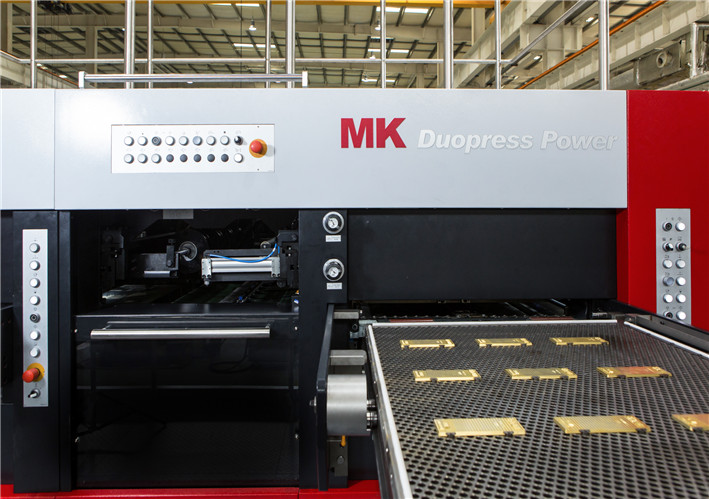

One-unit Foil Stamping Section

The new blowing & separating structure improves the effect of blowing & separating.

Optimized foil route makes operation more convenient.

Longitudinal multi-axis foil rack: can be selected long foil and indexing device

MasterSet

High-speed and high-precision image sensor

Multiple detection modes such as color mark, printing pattern and paper edge, etc.

Servo control system for high-precision register

Servo control system for high-precision register

Contactless paper transferring can avoid scratches of paper

MasterSet

High-speed and high-precision image sensor

Multiple detection modes such as color mark, printing pattern and paper edge, etc.

Servo control system for high-precision register

Servo control system for high-precision register

Contactless paper transferring can avoid scratches of paper

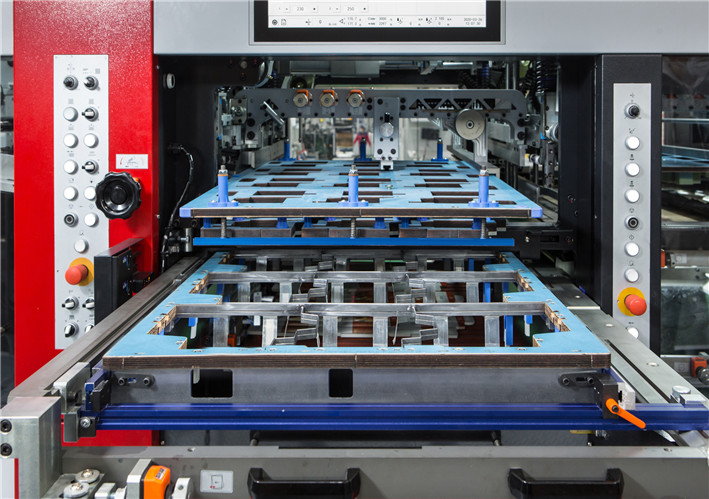

Two-unit Embossing Section

The new foil stamping main machine design provides excellent stamping results.

Unit I: 20 temperature zones and 40-180 ℃

The brand-new rotating gripper opening structure is designed to make the operation more stable and meet the needs of foil stamping and die cutting.

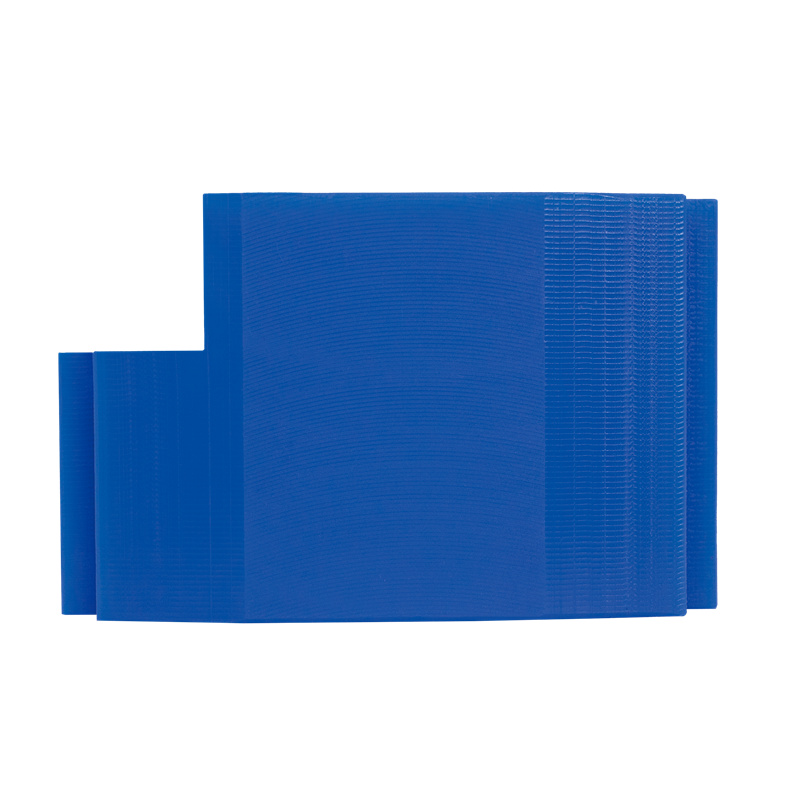

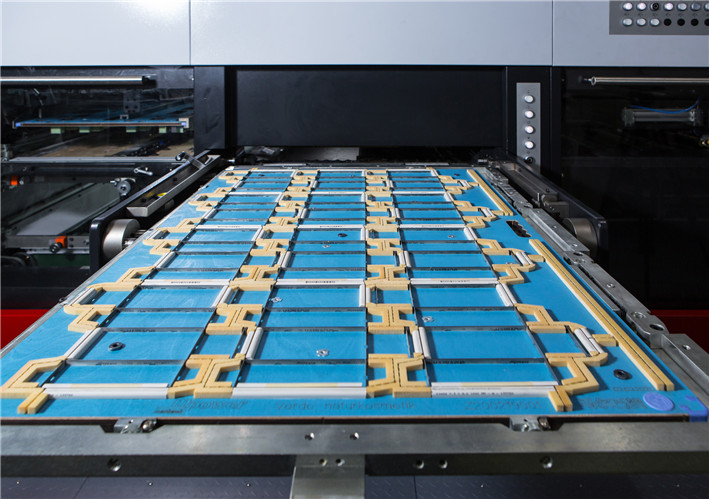

The new adjustable honeycomb plate structure

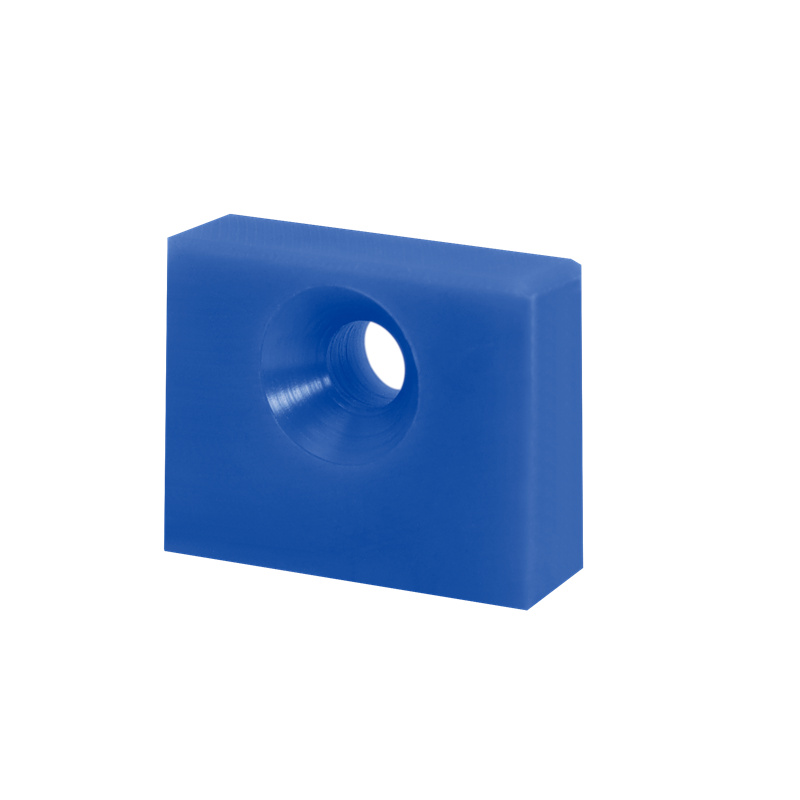

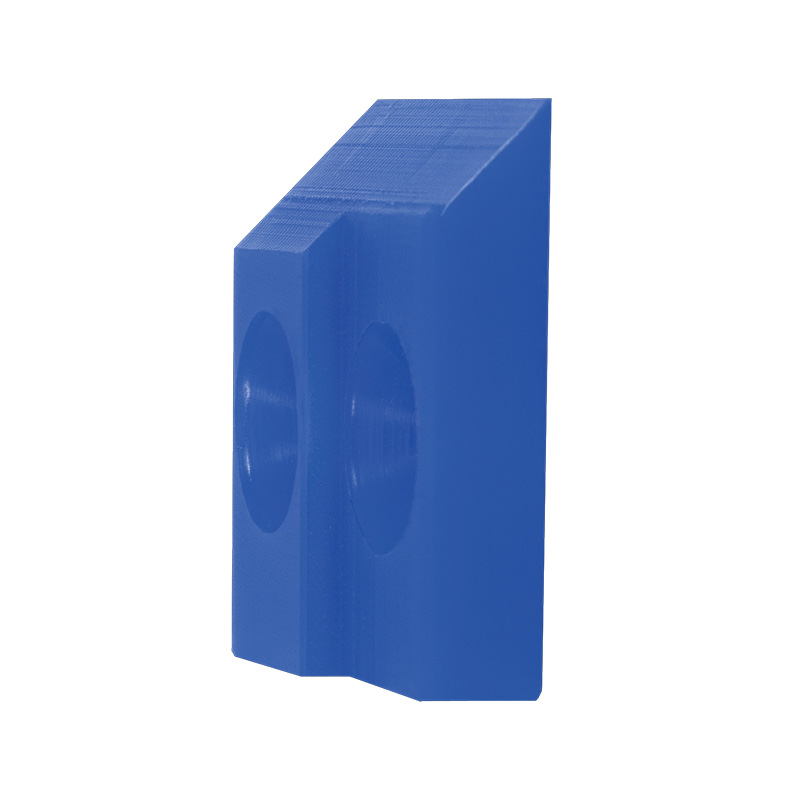

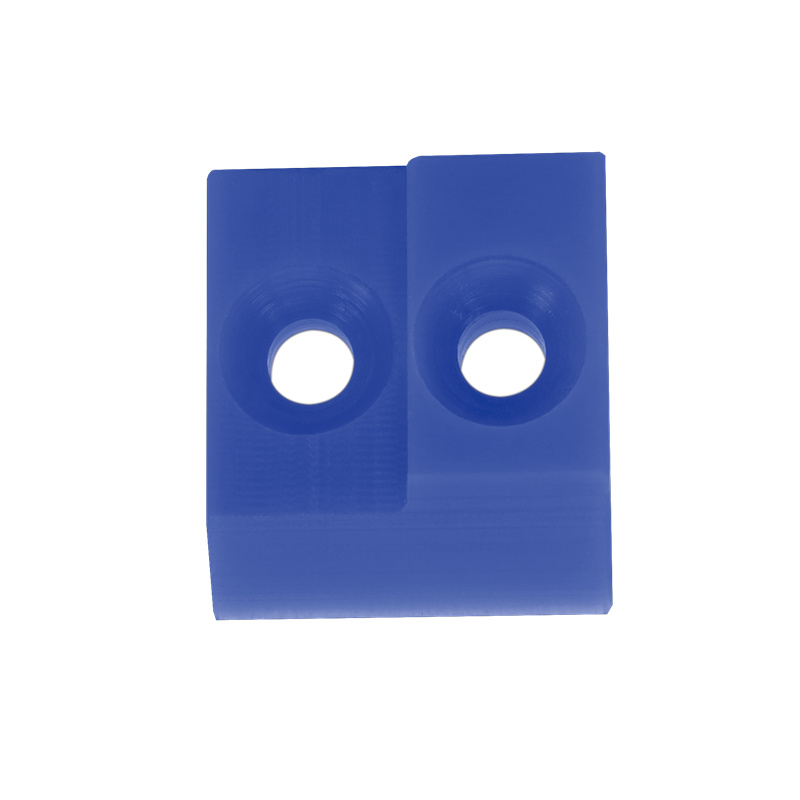

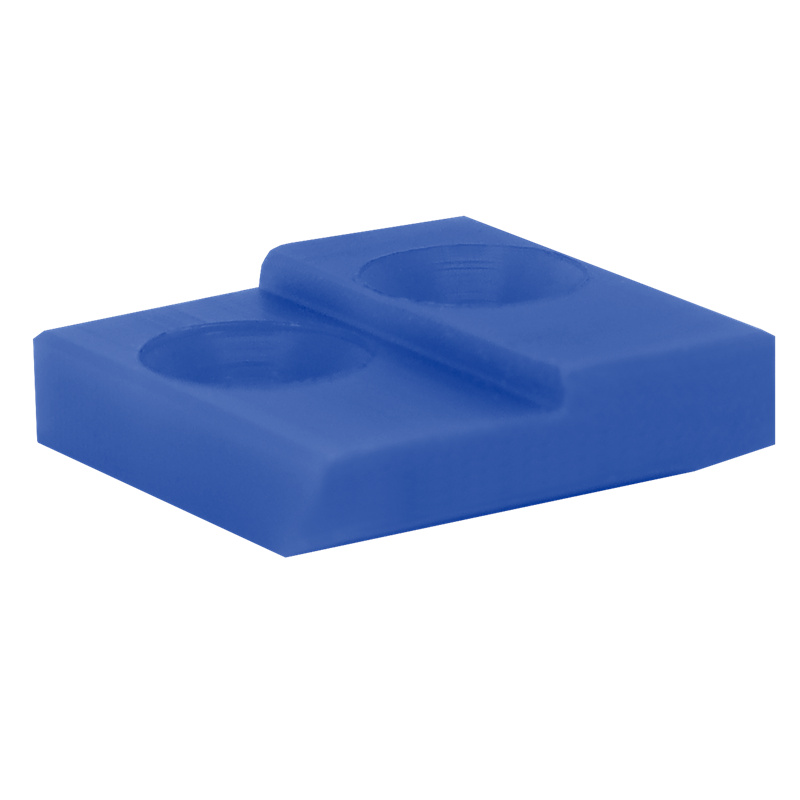

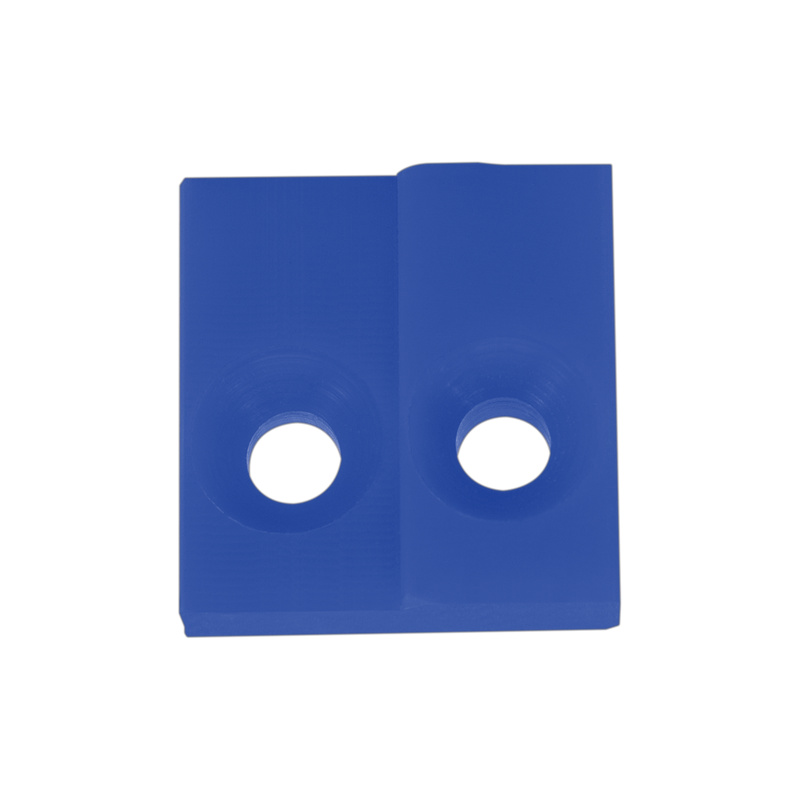

The new quick lock resin base plate

Servo automatic pressure regulating system

One click two-way toolless pneumatic locking device

Stripping Section

Second-generation accurately stripping tool quick lock system

Fine adjustment device with digital display

Stripping tools center positioning system

Pneumatic raising device of upper stripping frame

New stripping gripper bar positioning device

New air suction plate makes paper feeding smoother and more stable at high speeds.

Blanking Section

Second-generation accurately blanking tool quick lock system

Fine adjustment device with digital display

Blanking tools center positioning system

Pneumatic raising device of upper blanking frame

Automatic paper inserting and counting device

Automatic non-stop delivery device

New air suction plate makes paper feeding smoother and more stable at high speeds

Waste Edge Delivery Section

Waste edge delivery device

Non-stop sampling device

Servo drive brush

Control System

IPC industrial control system and industrial interconnection interface can be connected to Heidelberg Prinect system

21.5 inch large size true color touch HMI

Video monitoring system supports recording playback and screenshot

Video monitoring system supports recording, playback and screenshot

Simple interface and operation panel

New sampling table with large screen

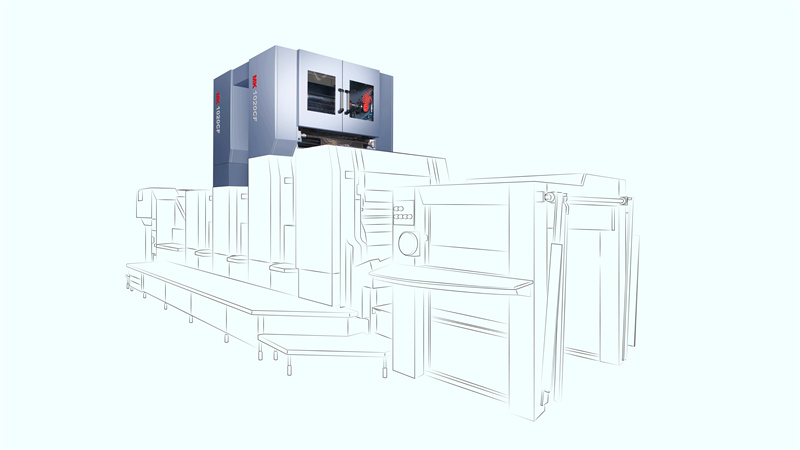

The new MP2020 foil stamping system

GS certification Masterwork Cloud Service with remote diagnosis, monitoring and maintenance

| Max. sheet size: | 1060mm x 760mm |

| Min. sheet size: | 400mmx350mm |

| Max. die ctting size: | 1060mmx 745mm |

| Max. stamping size: | 1060mmx 740mm |

| Gripper margin: | 9~17mm |

| lnner chase size: | 1096mmx770mm |

| Sheet specification: | 90~2000g/m2 cardboard 0.1 ~2mm cardboard Below 2mm corrugated paper (with MasterSet) |

| Max. working pressure: | 2.6MN |

| Electrical heating zone (only unit1 ) : | 20 zones,40-180°C adjustable |

| Foil width: | 20-1060mm |

| Foil feeding system of unit l: | 3 longitudinal (no crosswise) |

| Max. working speed: | 7000s/h* |

| Max. feeding pile height: | 1650mm (incl. pallet) |

| Max. delivery pile height: | 1300mm (incl. pallet, without recessed delivery) |

| Air source requirements:pressure: | 0.65~0.7Mpa, flow rate>1 m3/min |

| *The machine speed and accuracy will vary depending on the product type. Depending on the type of product, the speed and accuracy of the machine are different. | |

For more information, please download the PDF brochure, or click "Contact" to subscribe

Click download

-

hot stamping machines for sale

Highlights of this hot stamping machine:The Duopress Power 106FCSB die-cutting&stamping machine offers customized unit combinations with duopress technology.

For hot stamping machines with low prices and guaranteed quality, choose Masterwork.

-

Features of hot stamping machines include

High precision: The hot stamping machine can achieve precise hot stamping on different material surfaces, ensuring the quality and appearance of printed matter.

Versatility: Modern hot stamping machines often have multiple functions and can be used for different purposes such as hot stamping text, patterns, logos and decorations.

High efficiency: The hot stamping machine can quickly complete the hot stamping task, improve production efficiency and save time and costs.

Reliability: A high-quality hot stamping machine has stable performance and reliable operation, and can continue to work for a long time without failure.

Flexibility: Hot stamping machines often have the ability to adjust parameters such as temperature, pressure, and speed to accommodate different materials and printing needs.

Automation: Some hot stamping machines are equipped with automated control systems that can realize automatic feeding, hot stamping and discharge, reducing manual operations and improving production efficiency.

Related Products

Question consultation message

We provide complete product solutions, product manuals and more wonderful contents. Please leave your message and information below