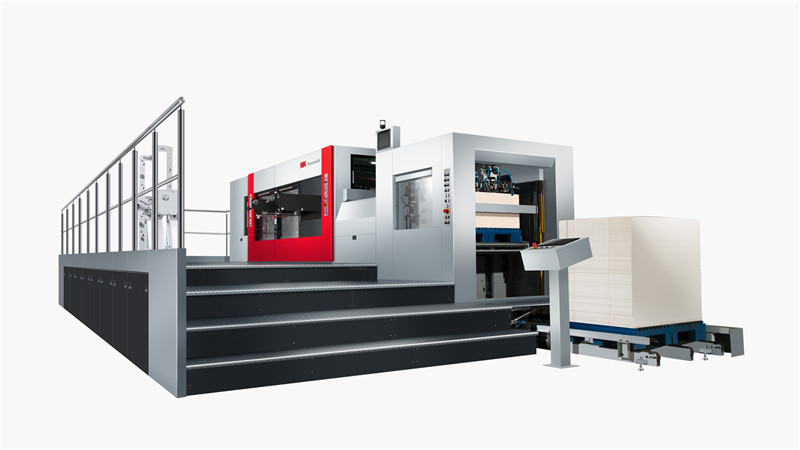

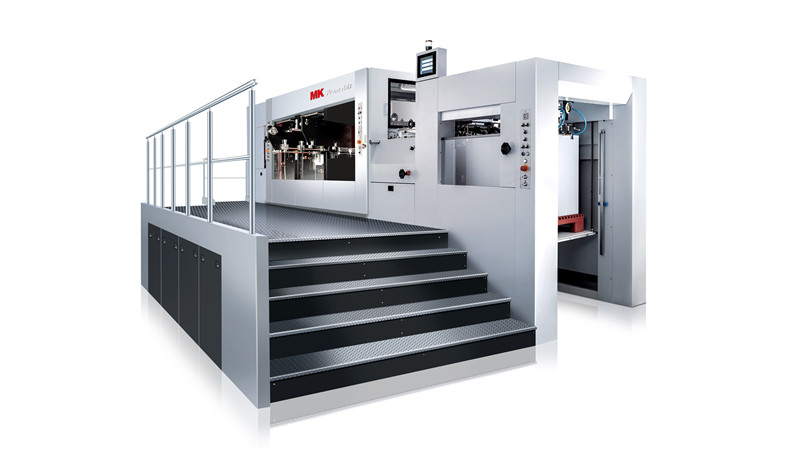

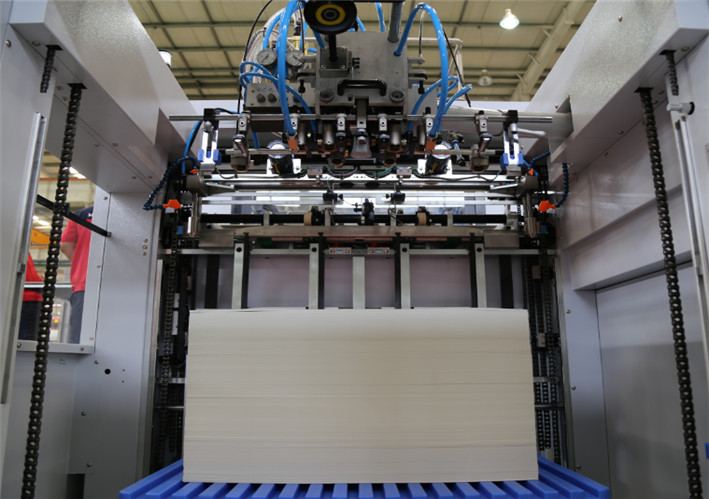

Non-stop Feeder

Suction head for paper, board, corrugated

Suction head with quick positioning function

Pile platform with motorized side alignment

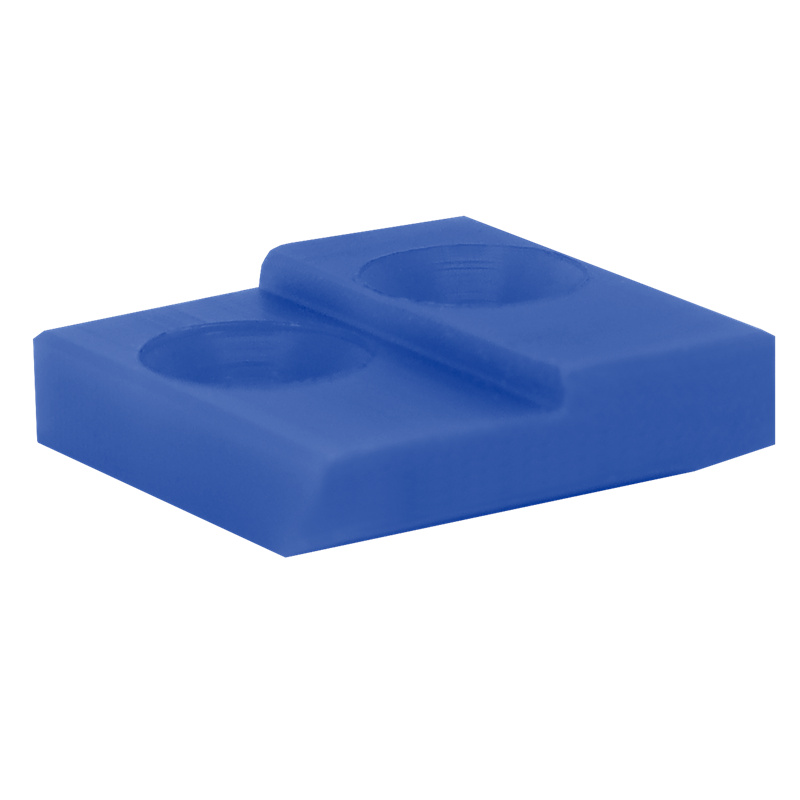

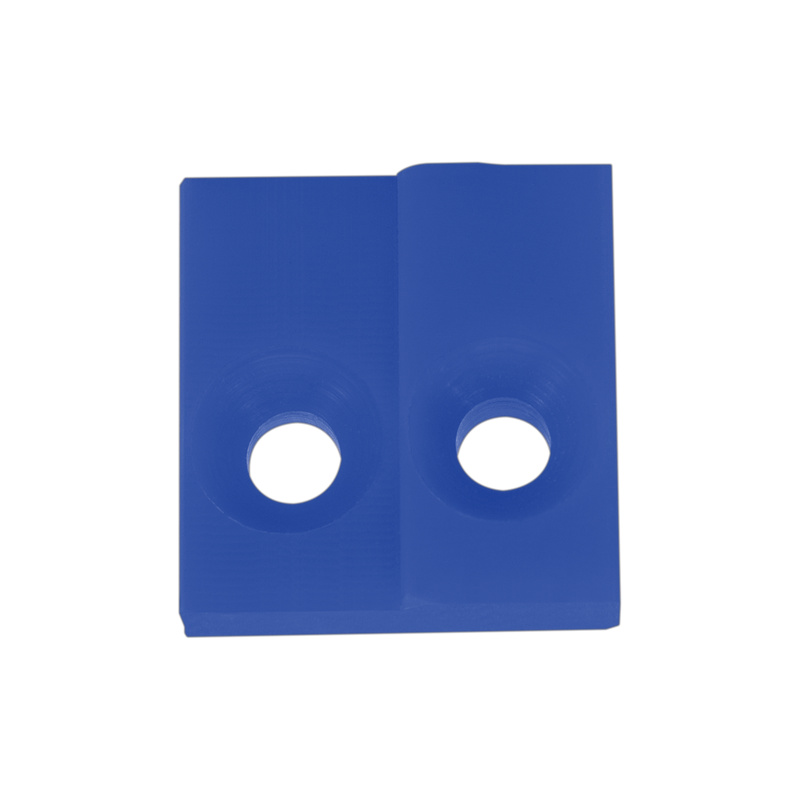

Mechanical double sheet detection

Feed Table

Register system

Pull/push side lay on operator and drive side

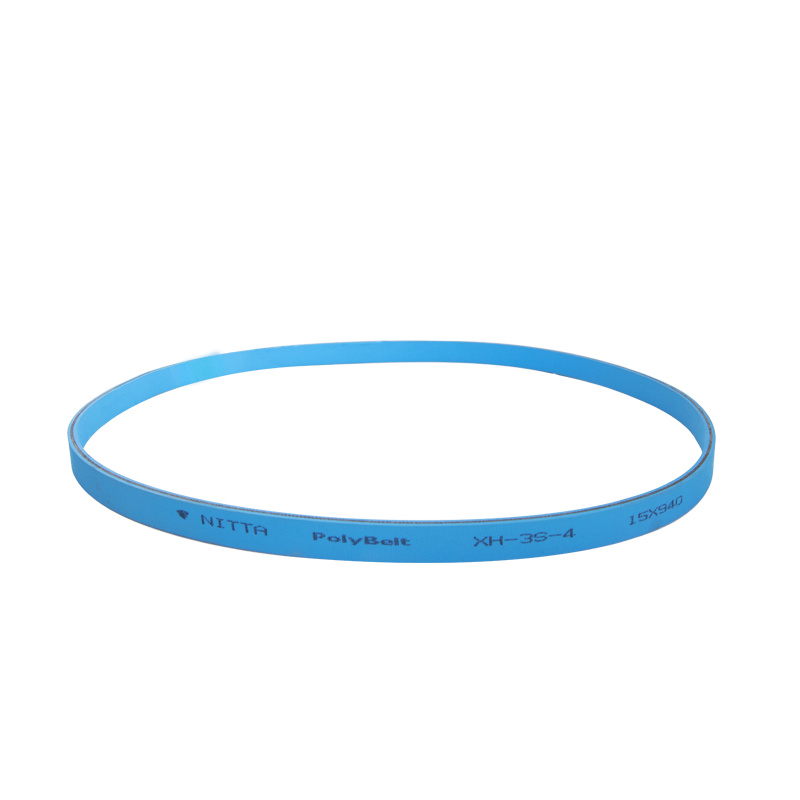

Suction belt table

Equippet with central positioning for rollers and brushes

Four front lays with activable optical monitoring

Ultrasonic double-sheet detector

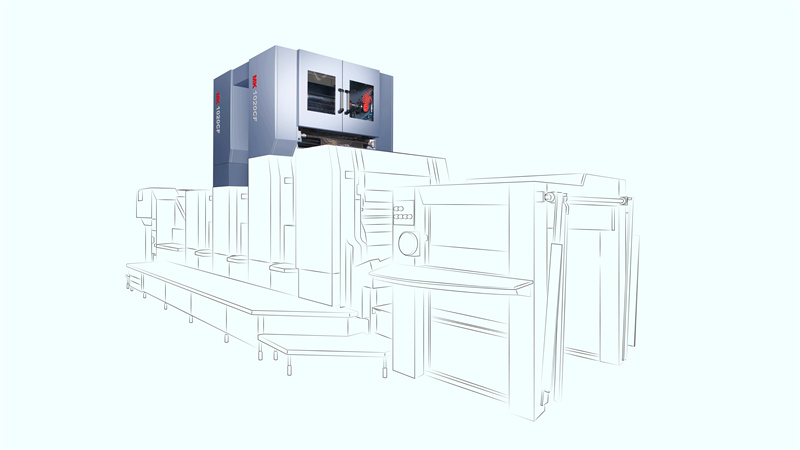

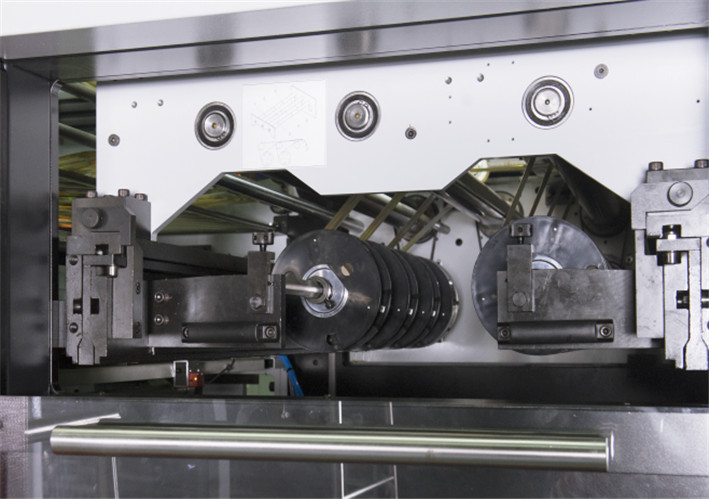

Platen Press

Register system

Motorized cutting pressure adjustment

Pneumatic locking and opening of upper and lower tools

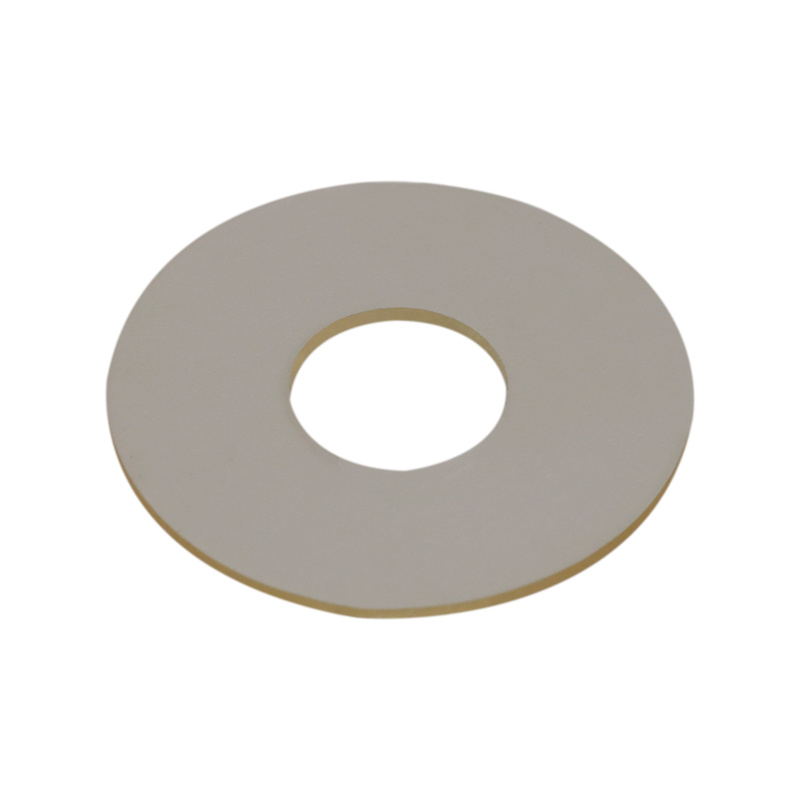

Cutting plate fine adjustment

Air cushion for easy cutting plate handling

Chase Changer (optional)

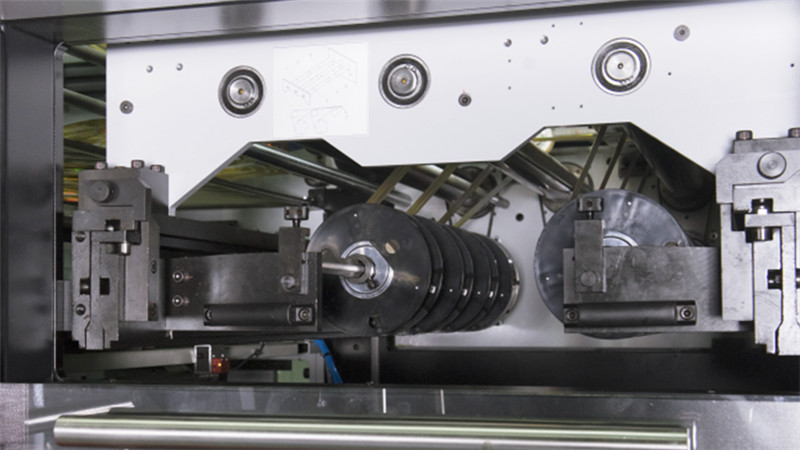

Hot Foil Unit

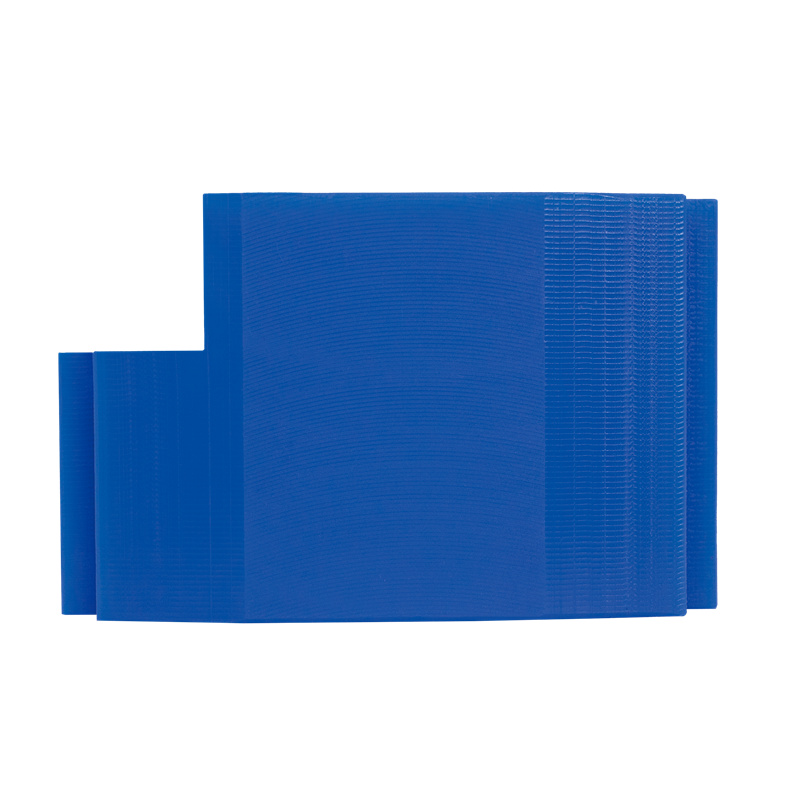

3 longitudinal foil feeding shafts

2 transversal foil feeding shafts

Hologram device (optional)

20 heating zones

Telescopic foil feeding bars

Motorized brush device for foil disposal

Rewinder (optional)

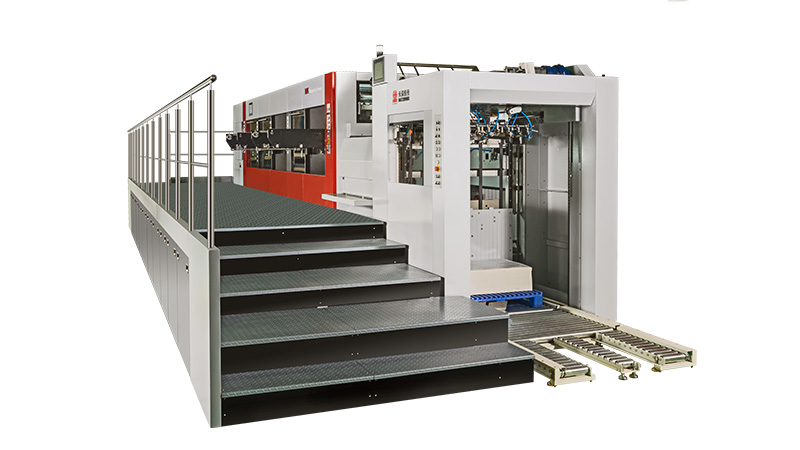

Delivery

Non-Stop rolling carpet

Pneumatic flap for test sheet removal

Motorized adjustment of brake brush power

Hot Foil Computer System

Calculation of foil feeding steps

Adjustment of temperature & cutting pressure

Regulation of the hologram application

Job data saving

Simulation of foil feeding steps

| Suitable Material | Promatrix 106 FC |

| Paper (min.) | 90 g/m2 |

| Cardboard (max.) | 2,000 g/m2 |

| Corrugated Borad (max.) | 4.0mm |

| Performance Date: | |

| Sheet size (max.) | 760x 1,060 mm |

| Sheet size (min.) | 300 x 350 mm |

| Cutting pressure (max.) | 3.0 MN/ 300t |

| Machine speed (max.) | 7,500 sph |

| Hot Foil Stamping: | |

| Hot Foil speet | 7 ,500 sph |

| Hologram (option) speed | 5,500 sph |

| Temperature max. | 180°C |

| Number of heating zones | 20 |

| Foil reel diameter: | |

| Longitudinal | max.250 mm |

| Transversal | max. 200 mm |

| Foli width | 20-1,060 mm |

| Pile Heights (incl. pallet): | |

| Feeder pile (max.) | |

| ohne Non-Stop | 1 ,500 mm |

| with Non-Stop | 1 ,200 mm |

| Delivery pile (max.) | 1 ,400 mm |

For more information, please download the PDF brochure, or click "Contact" to subscribe

Click download

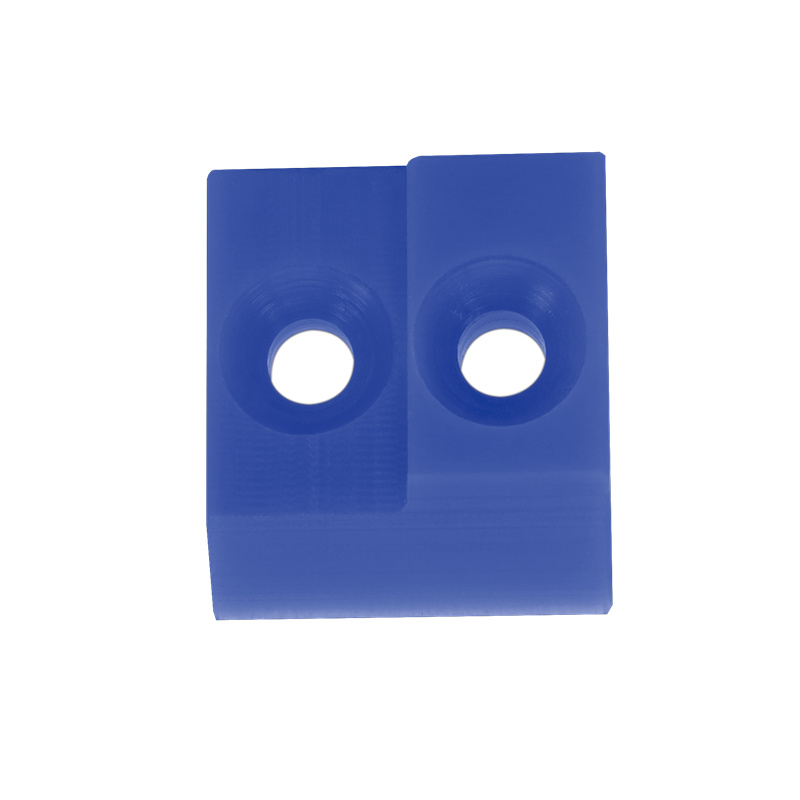

Related Products

Question consultation message

We provide complete product solutions, product manuals and more wonderful contents. Please leave your message and information below