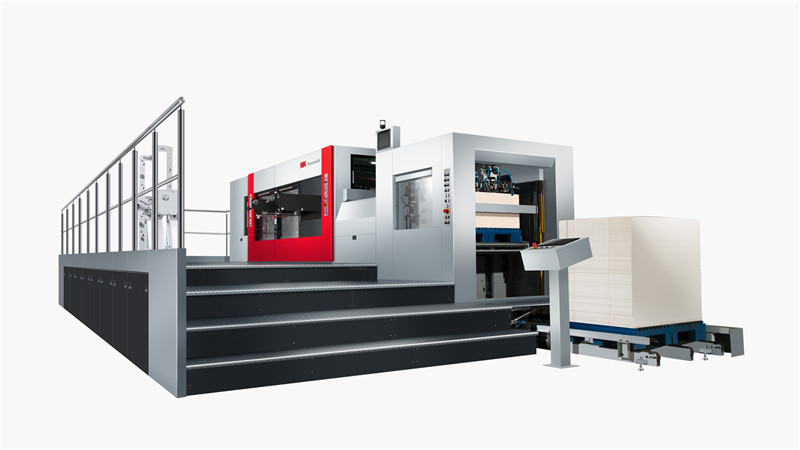

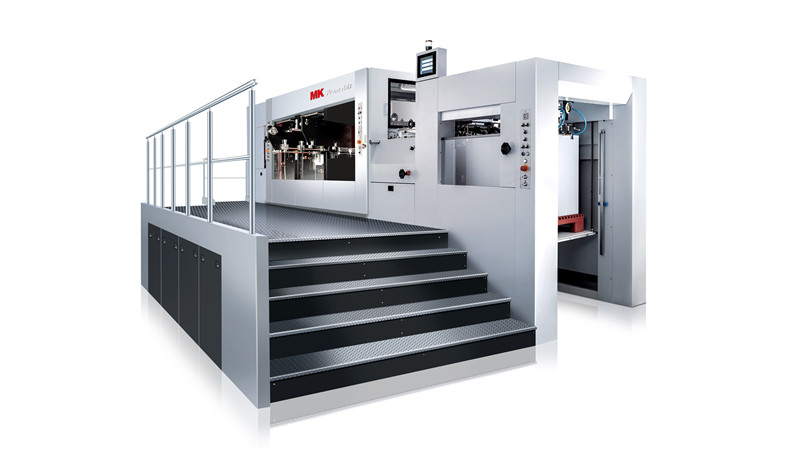

Feeding Station

Feeder drive by servo motor

Paper feeding automatic lifting device

Stream type feeding device

Manually adjust the vertical position of the feeder head

Manually adjust the horizontal position of the feeder head

3 anti-collision devices

Manual lateral side blowing device and side baffle

Vacuum feeding table

Manual lifting device for paper feeding frame

Ultrasonic double- sheet detector

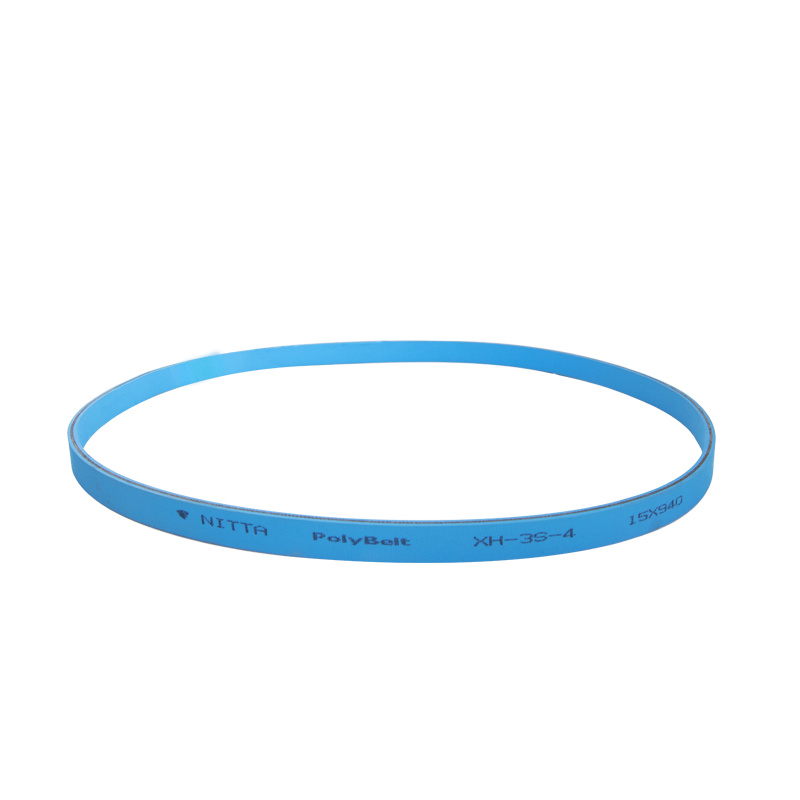

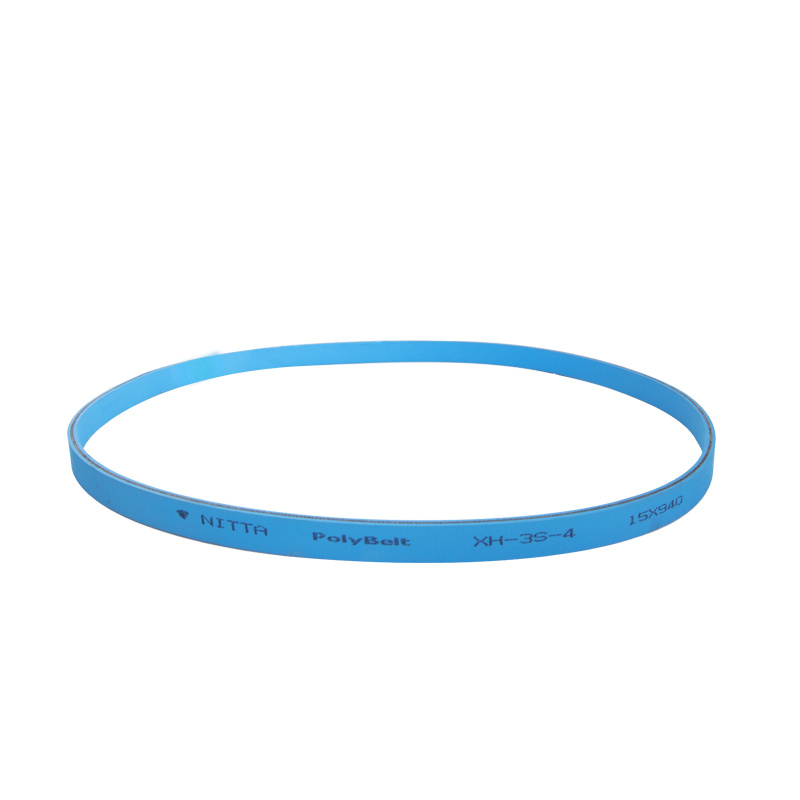

Imported feeding belt

MasterSet

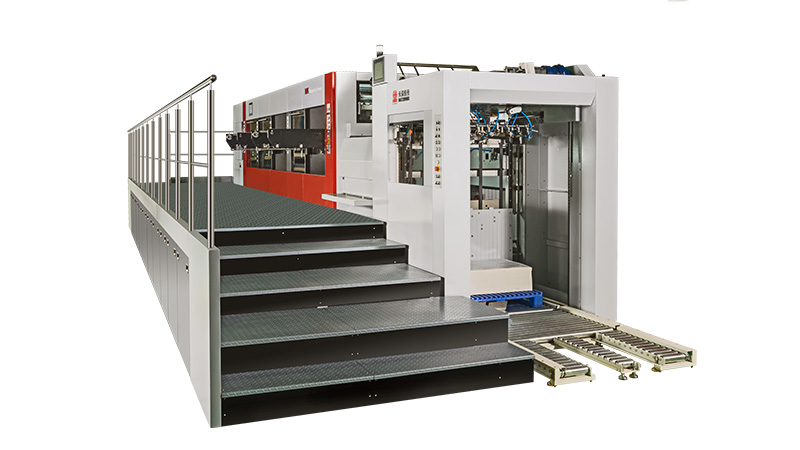

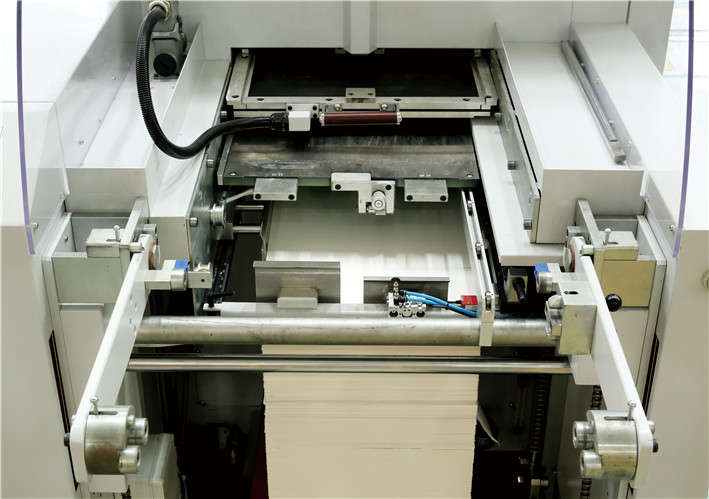

Main Machine Station

Main machine power and gripper bar are controlled by servo motor

Pressure adjusting is auto controlled by servo motor

Adjustable cutting plate equipped with 2+2mm steel plate

MC and electronic cam controlled the die cutting timing sequence

Die cutting chase overturn device

Bi-directional pneumatic lock device of die cutting chase

Adjustable cutting plate with pneumatic locking device

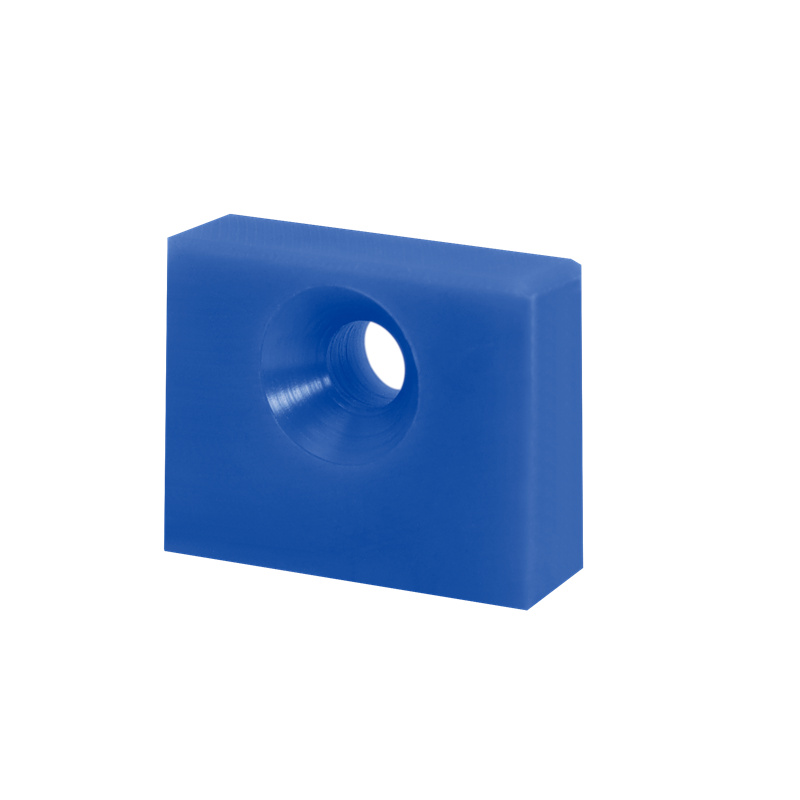

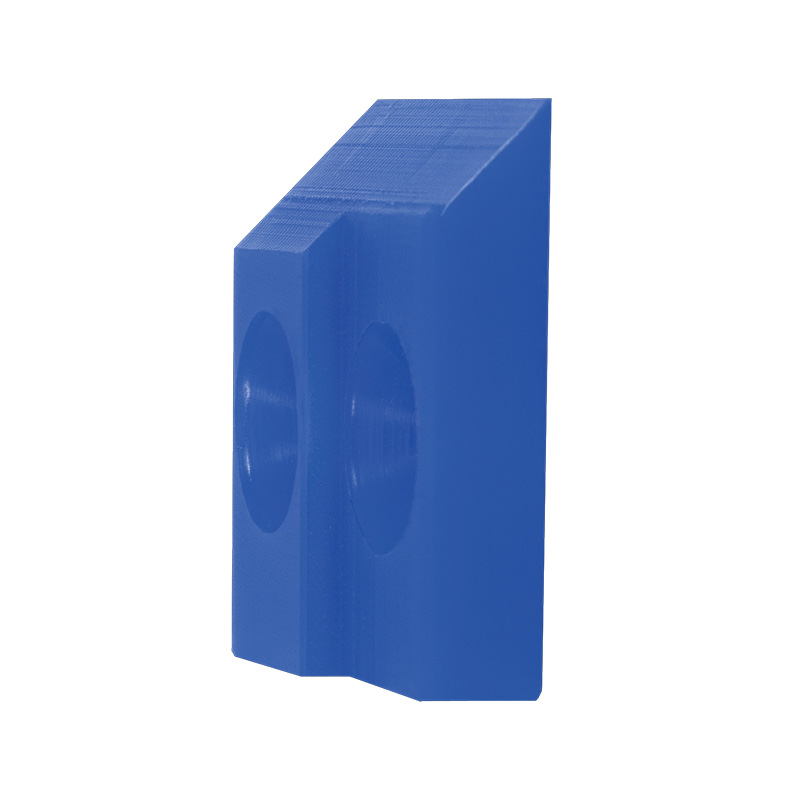

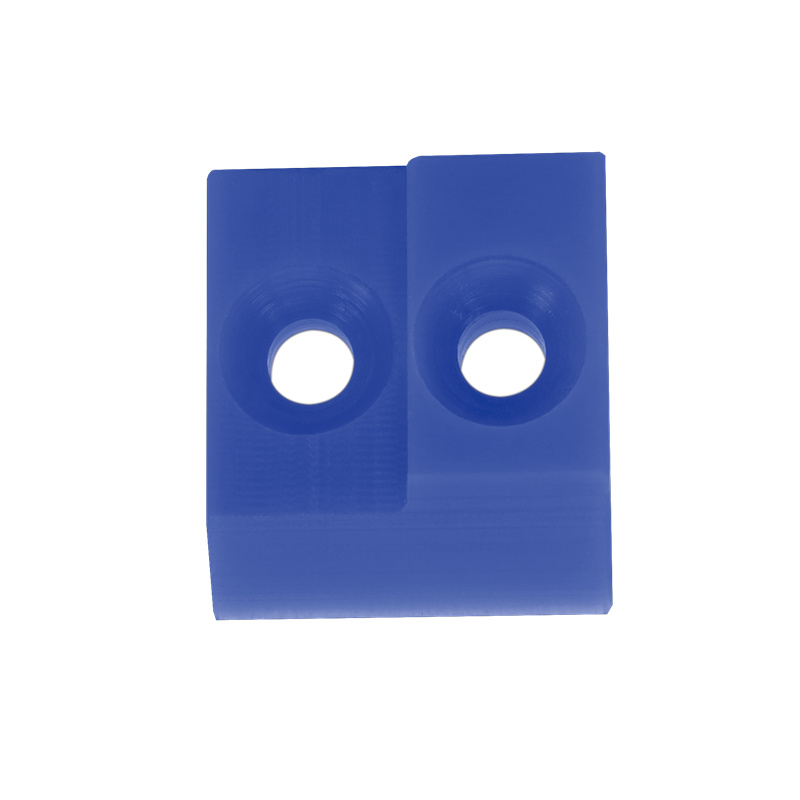

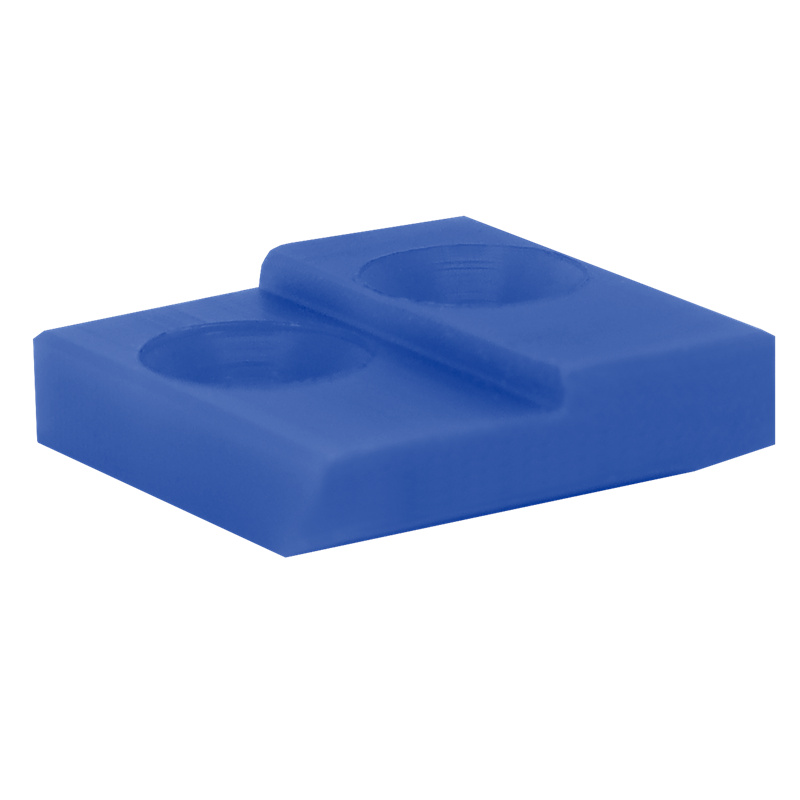

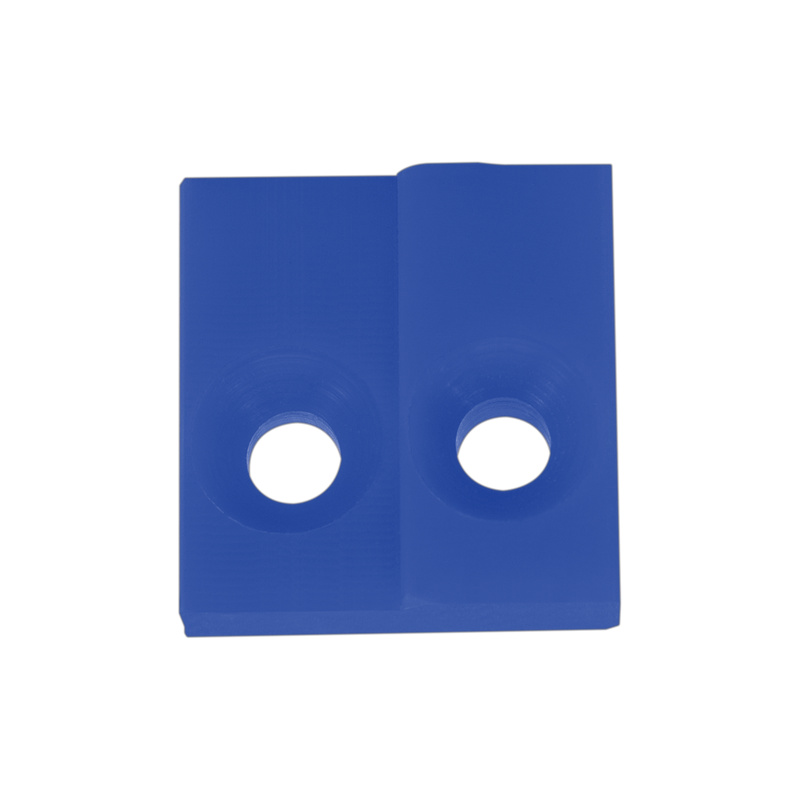

Quick change honeycomb plate

Quick lock die cutting chase

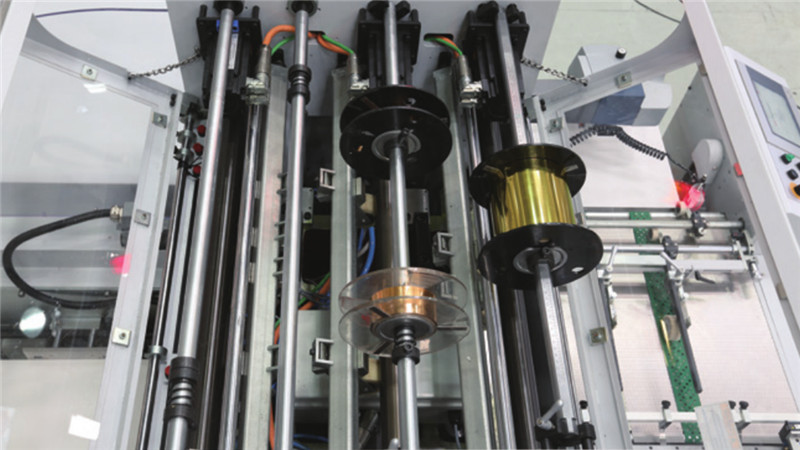

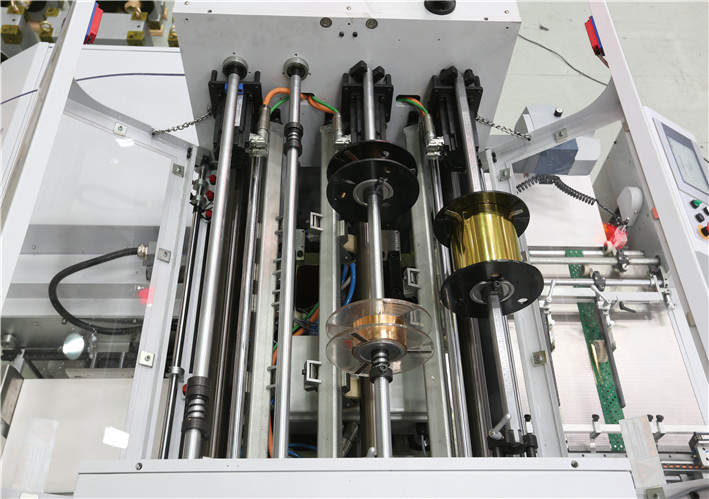

Foil Stamping Station

Two foil shafts with winding/unwinding foil system controlled by servo motor. The max.

Blowing separation device

Foil detection system

Motorized adjusting for the foil collection damp

Pneumatic foil pressing rubber roller lifting

Delivery Station

Bi-directional pneumatic sheet aligning device

Delivery auto down device

Counting paper-inserting system (optional)

Electrical Monitoring System

Imported true-color HMI 10.4'

Operation panel

MC drives, etc. are all well-known European brands

GS standard, and adds safety module control and safety circuit detection.

Double circuit multi-touch redundancy design

Temperature control with redundancy protection function. This prevents the temperature from rising too high.

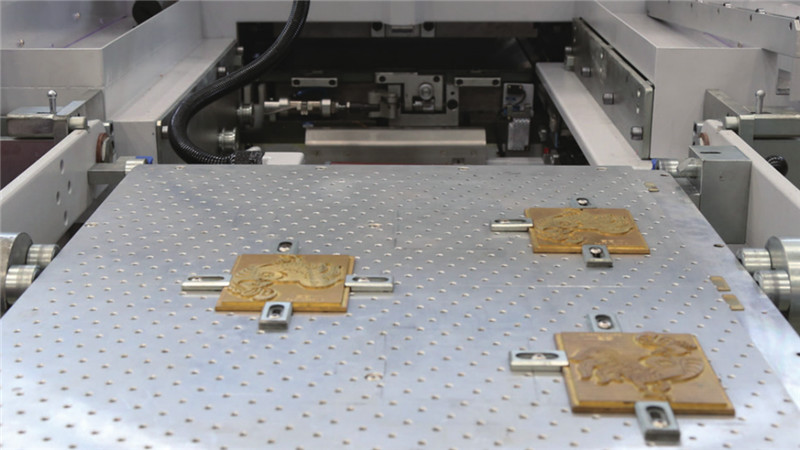

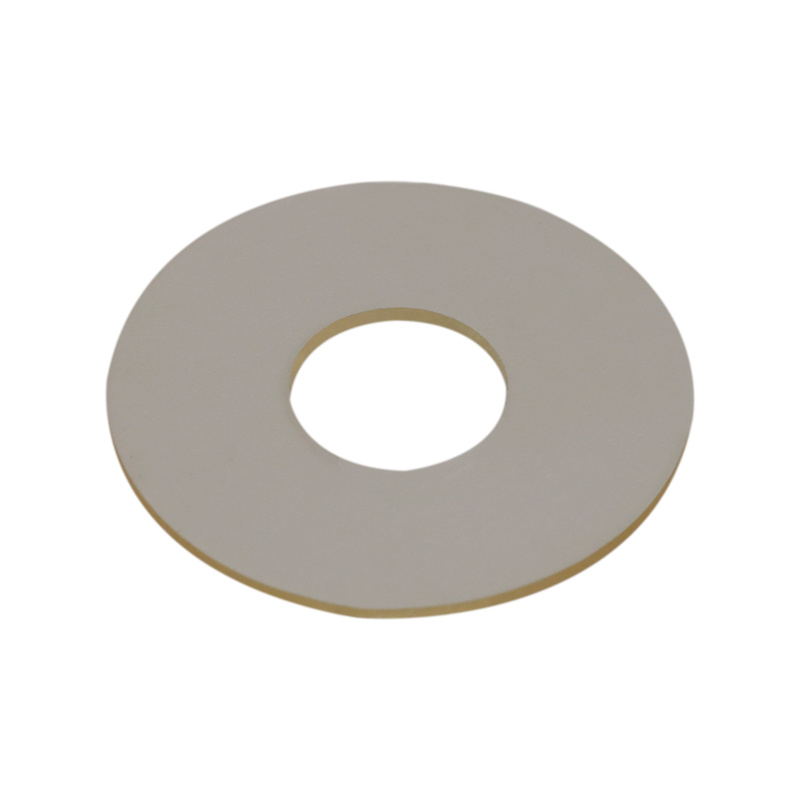

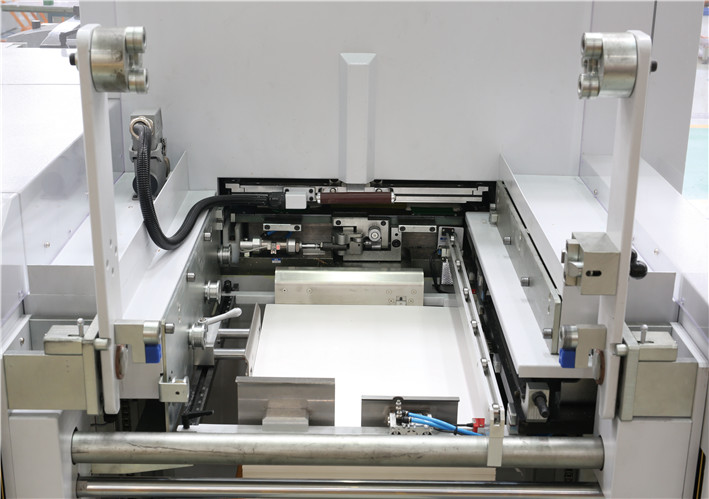

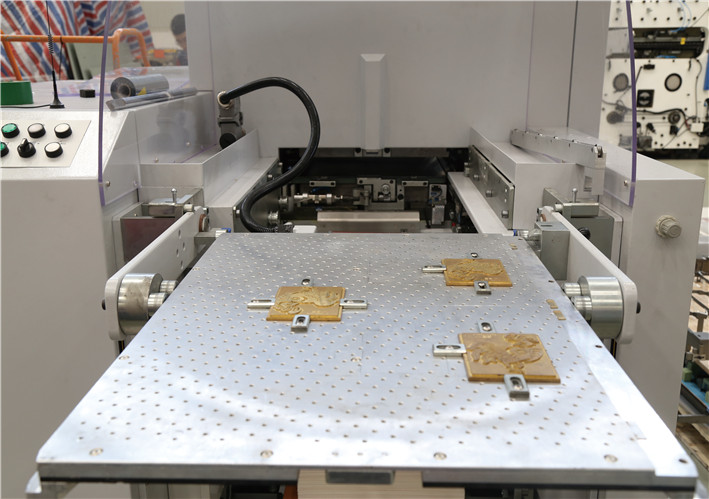

Quick Change Honeycomb Plate

The quick change honeycomb plate directly inserts the heating tube into the honeycomb plate, so it has the advantages of short heating time (15-20 minutes) and low energy loss.

There is a thermal insulation layer above the heating pipe. After a long time of foil stamping, the upper platform is still at normal temperature, and the die-cutting chase can be directly replaced for die-cutting work, and the change is only ±0.03mm under normal-temperature die-cutting pressure. This makes the conversion fast and does not have to wait.

4 temperature zones, 40~180℃ adjustable

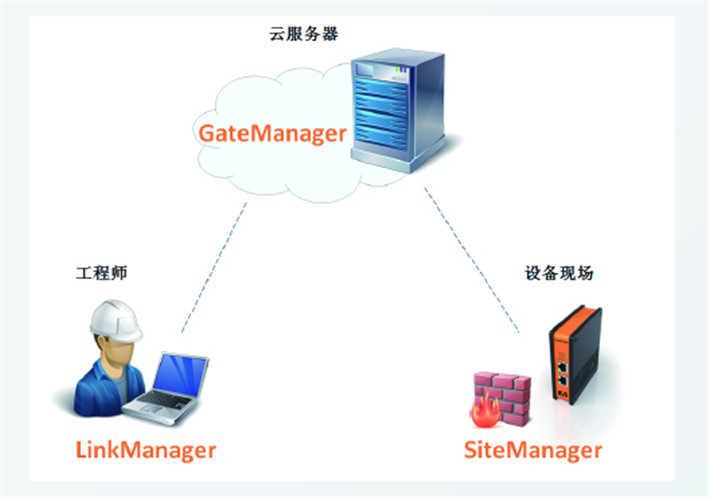

Remote Monitoring System

Remote connection channels are Web-based SSL/STL security protocols. This remote maintenance solution guarantees the security of user data and high firewall accessibility, which is both safe and convenient.

It can monitor field devices, promptly remind customers to repair or maintain equipment.

When the mechanical equipment is abnormal, remote monitoring system can be quickly detected and remotely debugged to reduce troubleshooting time.

| Technical Data | Multimatrix60FC |

| Max. sheet size: | 600mmx 450mm |

| Min. sheet size: | 250mmx 175mm |

| Max. die cutting size: | 590mm x 430mm |

| Gripper margin: | 9~ 17mm |

| Inner chase size: | 610mmx 452mm |

| Suitable material: | 120~ 600g/m2 (cardboard) |

| 0.15~0.8mm (cardboard) | |

| Die cutting accuracy: | ≤+0.10mm (die cutting and regular foil stamping)* |

| Max. working pressure: | 80T |

| Max. working speed: | 5500s/h (die cutting and regular foil stamping)* |

| Max. feeder pile height: | 850mm (incl. pallet) |

| Max. delivery pile height: | 850mm (incl. pallet) |

| Dimension: | 3100mm (L)X 1980mm (W)X 2300mm (H) |

| Weight: | ≈5300kg |

| Full-load power: | 26.3KW |

| Air source requirement: | Pressure 0.6 ~0.7Mpa, Flow rate> 1 m3/min |

For more information, please download the PDF brochure, or click "Contact" to subscribe

Click download

Related Products

Question consultation message

We provide complete product solutions, product manuals and more wonderful contents. Please leave your message and information below