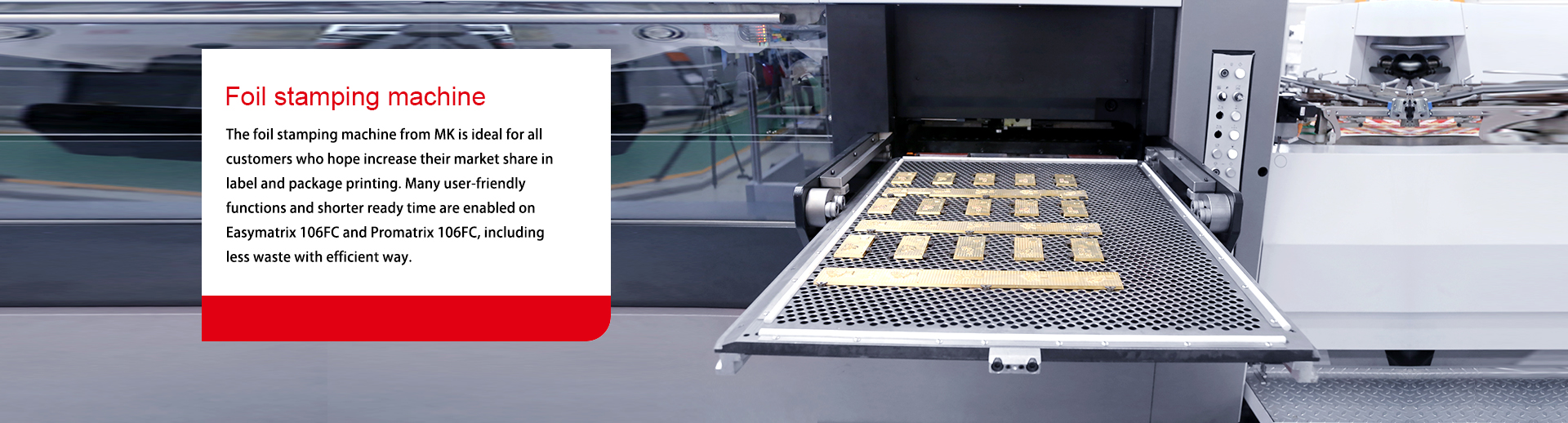

High efficiency: Masterwork automatic hot foil stamping machine is able to perform stamping operations quickly, which significantly increases the production speed. Its automation feature reduces human intervention and downtime.

High precision: the automation control system ensures that the position and strength of each stamping is accurate and consistent, reducing errors in traditional manual operations and improving product quality.

Save labor: automated operation reduces the dependence on human labor, only a small number of operators are needed to supervise and control the equipment, thus reducing labor costs.

Stability: Full-automatic hot stamping machine can run stably for a long time, ensuring the continuity of the production line and reducing the downtime caused by equipment failure.

Versatility: many full-automatic hot stamping machines support the processing of a wide range of materials, including paper, plastic, leather, fabric, etc., applicable to a variety of industry needs.

Environmental protection and energy saving: modern automatic hot stamping machines usually adopt energy-saving design, which reduces energy consumption, and some of them use environmentally friendly materials for stamping, which is more in line with the needs of sustainable development.

Strong consistency: automated control not only improves production speed, but also ensures the consistency of product quality and stamping effect in each batch, reducing unqualified products.

Reduced scrap rate: due to precise operation and stable control, the use of automatic stamping machine can effectively reduce the production of scrap and reduce material waste.