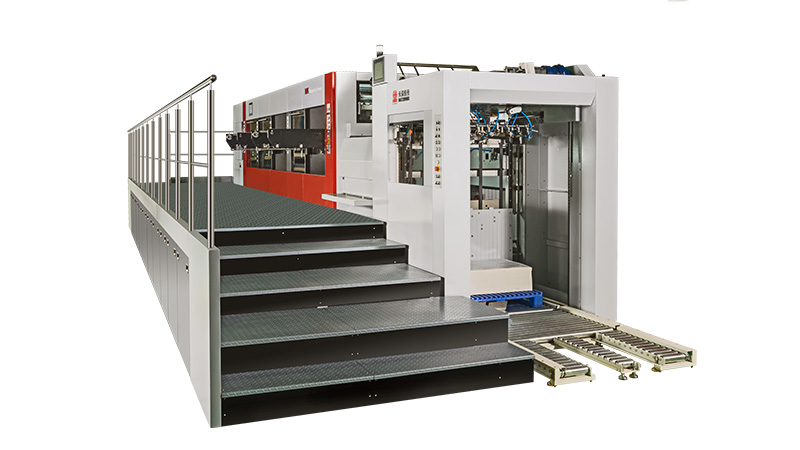

Feeding Unit

Push-pull dual-purpose side lay, easy to switch between push and pull lay

Equipped with a deceleration mechanism, the paper reaches front lay more smoothly

High-speed clutch, the main unit can run separately. which is convenient for sampling and plate adjustment. shortens the adjustment time

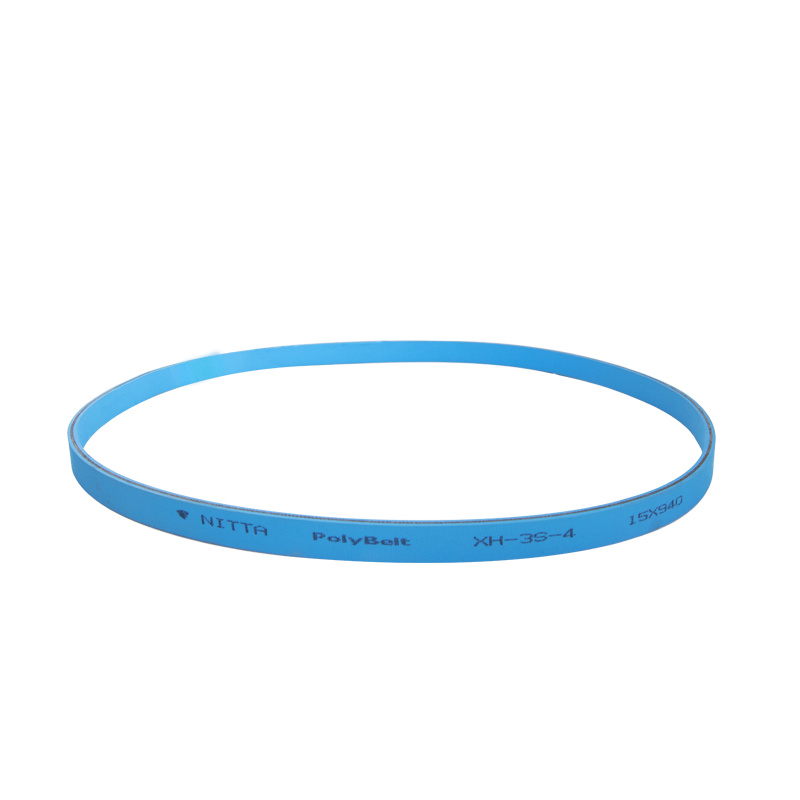

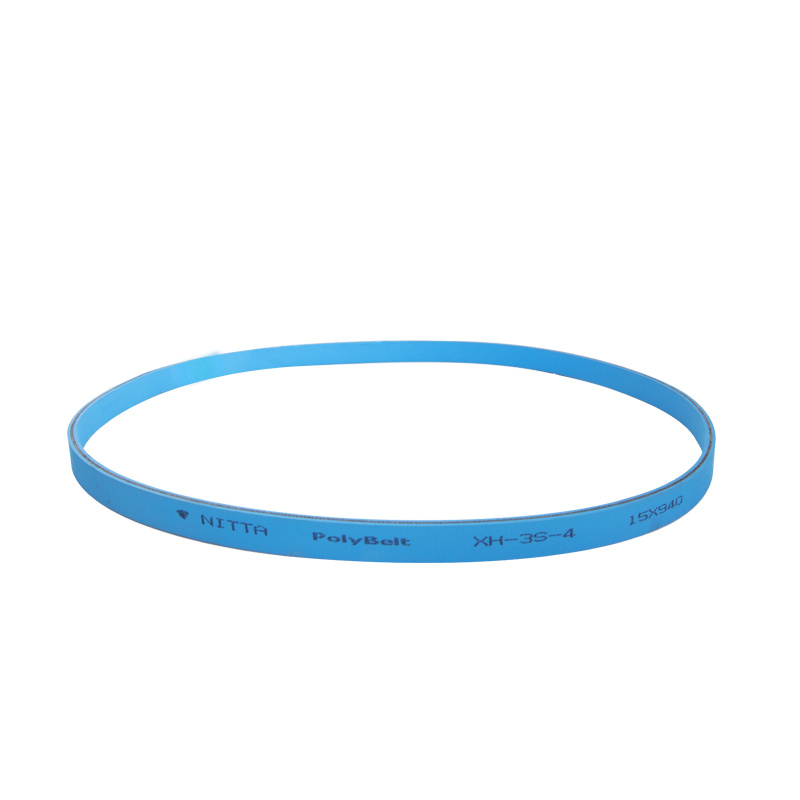

Maintenance-free synchronous belt drive more stable

Ultrasonic double sheet detection (optional)

Manual paper pile lateral adjustment, operation simple and convenient

Becker vacuum pump

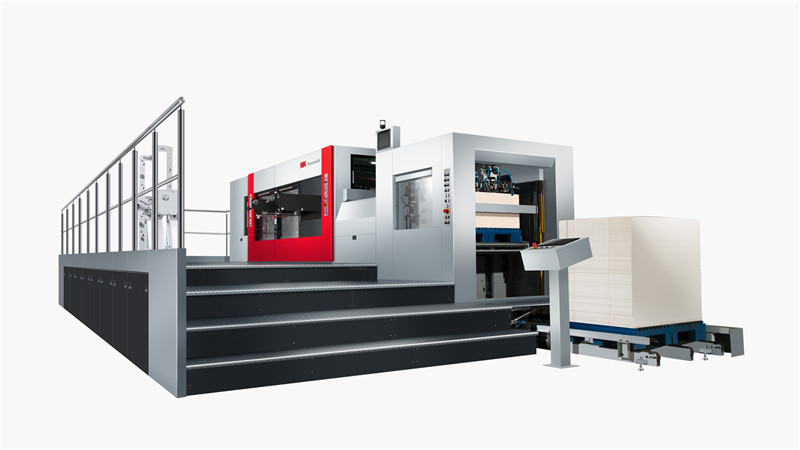

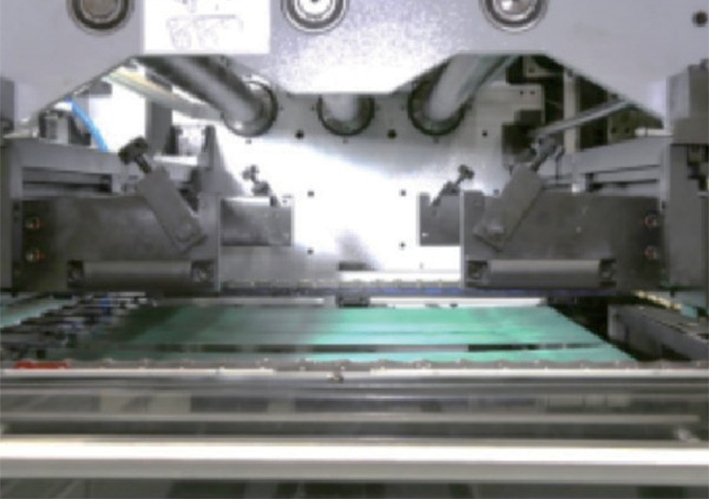

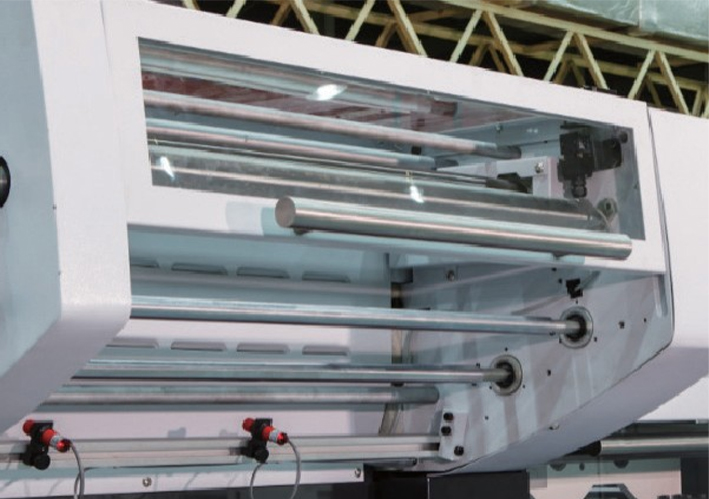

Foil stamping unit

Foil control computer system

Three shafts longitudinal foil feeding system

One shafts horizontal foil feeding system

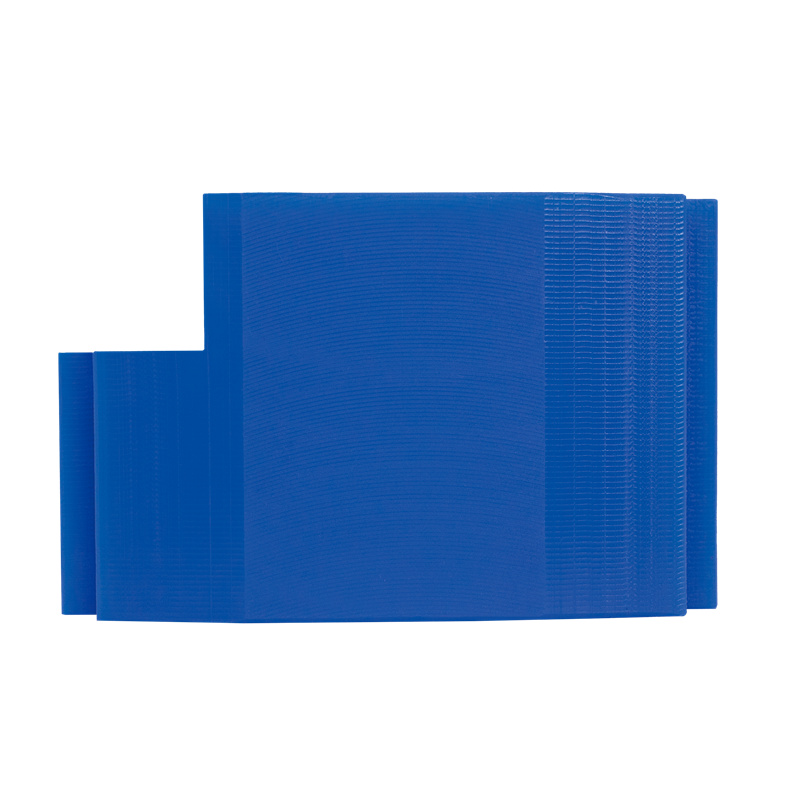

External brush roller waste foil collection device

Holographic hot stamping control system (optional)

Optional longitudinal 6 shafts, transverse 2 shafts

The maximum foil diameter is 250mm

Transverse foil control unit

Transversal foil feeding, more stable

Waste foil collection in OS operation more convenient

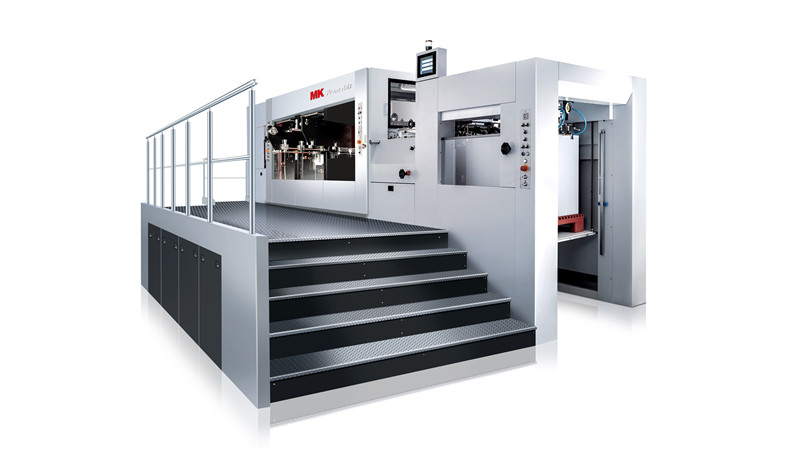

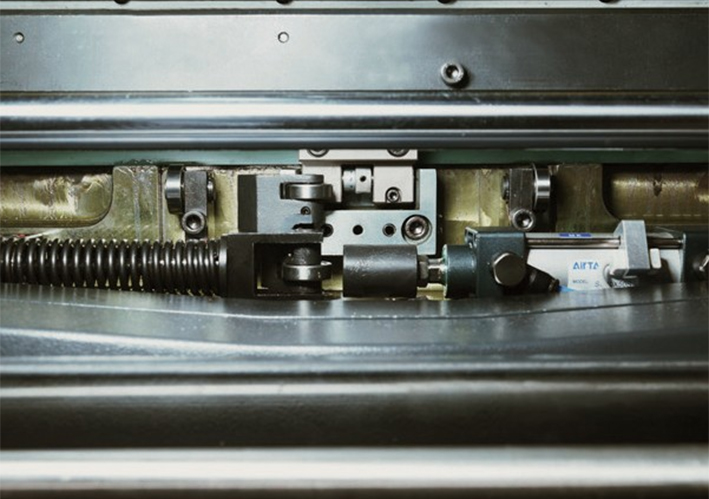

Die-cutting Unit

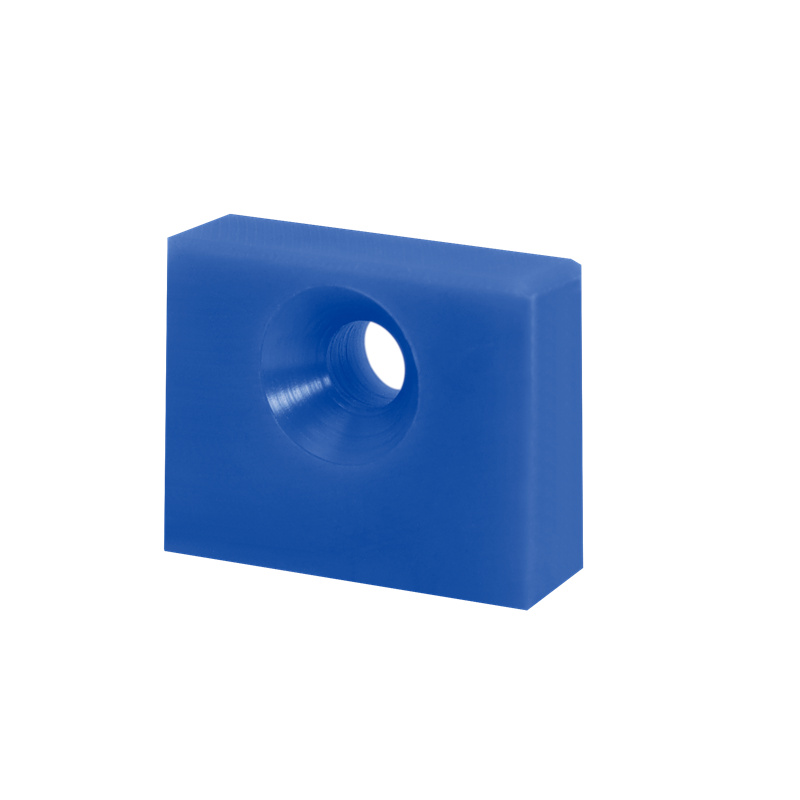

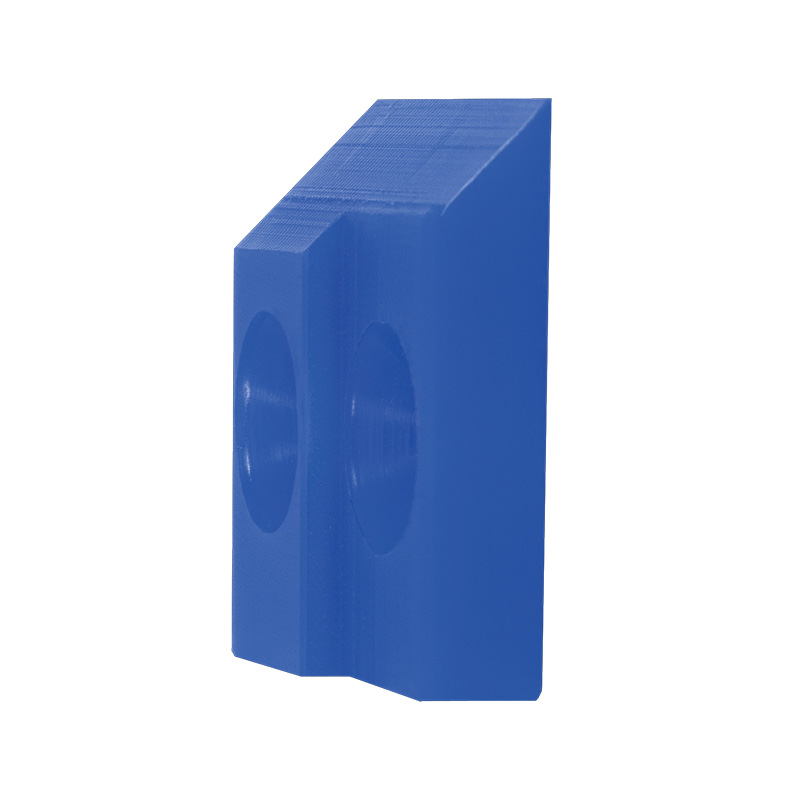

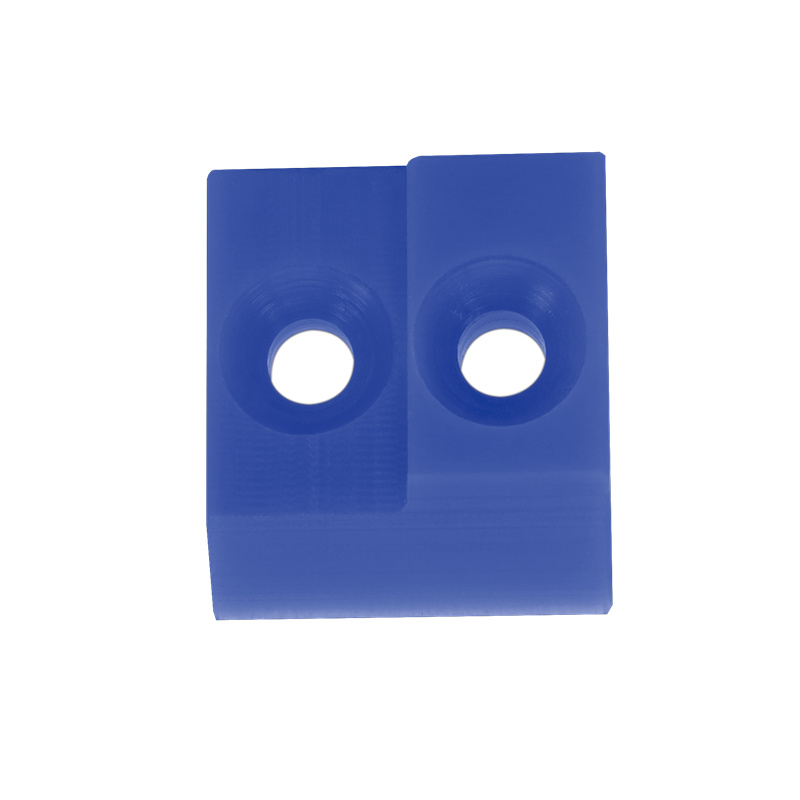

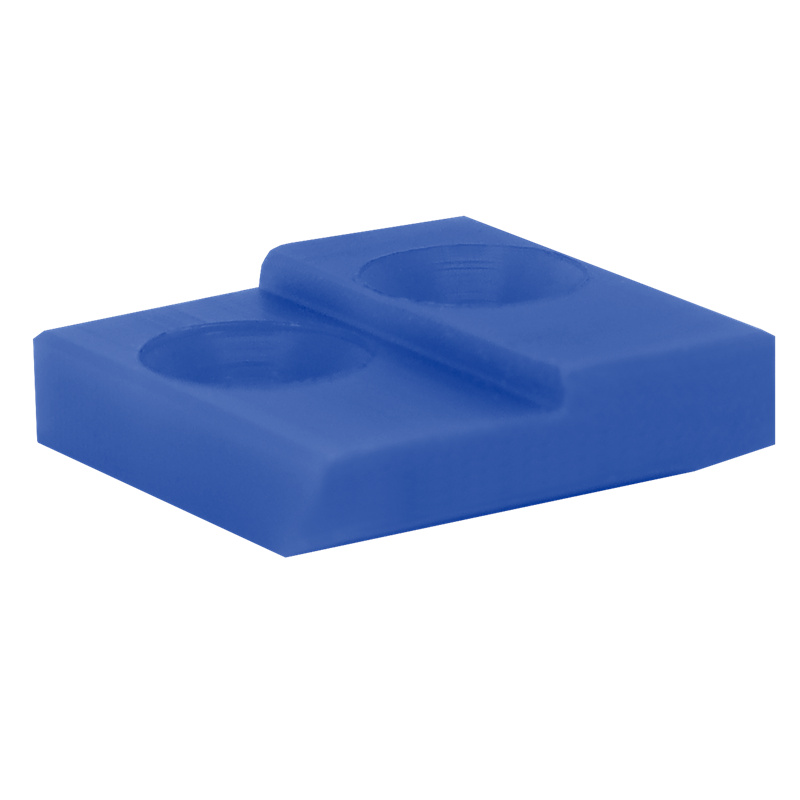

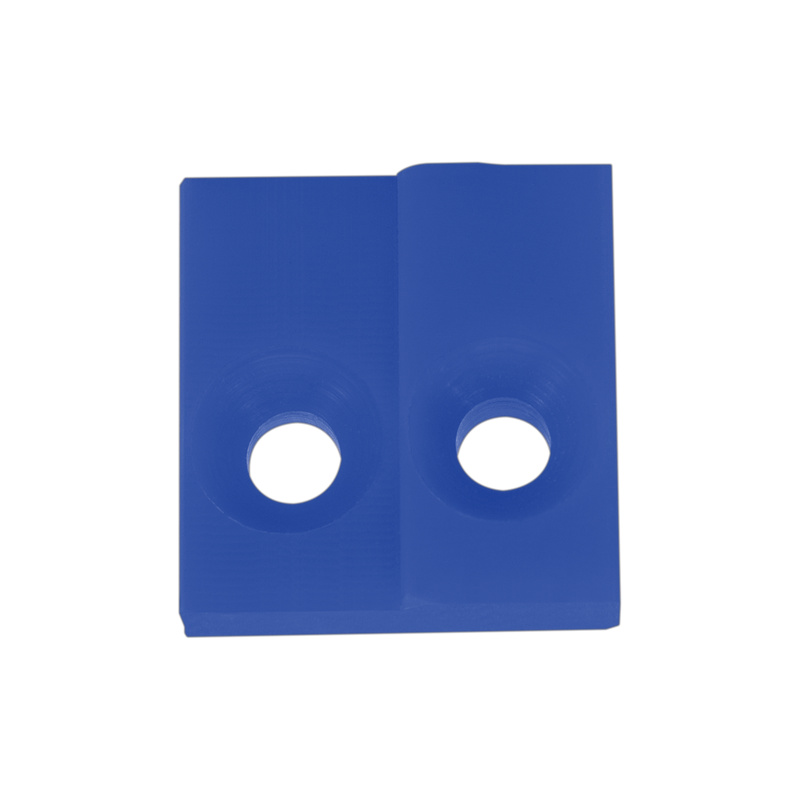

Combined base plate with a fine-tuning function

Extended connecting rod to increase the pressure holding time

Bidirectional pneumatic locking device for chase and base plate

High quality main chain, patented front lay compensation mechanism, improve machine accuracy

20 independent temperature control zones , the temperature difference is ≤+5°

High quality intermittent box

Servo automatic pressure regulation mechanism

Delivery unit

Mechanical bidirectional paper alignment device

Pneumatic sampling device

Control system

New hot stamping control system has the function of non-stop pressure adjustment, the operation interface is more friendly

Equipped with high-end circuit safety module.reach level 4 safety protection

Mitsubishi PLC, the calculation and execution speed is faster, stable and reliable

Modular design for easy maintenance(control and safety protection)

| Maximum sheet size | 1300 x 960mm |

| Minimum sheet size | 550mmx450mm |

| Maximum die cutting size | 1300 x 945mm |

| Maximum hot stamping size | 1300 x 9740mm (machine running direction) |

| Gripper margin | 9~17mm |

| Paper | Cardboard: 0.1-2mm (90-2000 gsm) Corrugated: Max.4.0mm, flatness< 20mm/m2 |

| Max.operating pressure | 300T |

| Die cutting accuracy | ≦±0.10mm (die-cutting and hot stamping); ≦±0.20mm(optional holographic foil stamping) |

| Max. working speed | 6000s/h (optional holographic hot stamping: 5500s/h) |

| Max. feeding pile height | 1,300 mm(including wooden pallet) |

| Max. delivery pile height | 1,100mm(including wooden pallet) |

| Electrical heating zone | 20 zones (Individual adjustable from 40-180 ℃) |

| Max. diameter of foil roll | Machine direction /Longitudinal direction: 250mmTransversal direction: 200mm |

| Width of aluminum foil | 20~1300mm |

| Main motor power | 15KW |

| Overall weight | 25T |

| Overall dimensions (L x W x H) | 7481mm x 5124mm (including operation platform) x 2480mm |

| Air source requirements | Pressure 0.6~0.7 MPa, flow rate ≥0.8 m³/h |

For more information, please download the PDF brochure, or click "Contact" to subscribe

Click download

Related Products

Question consultation message

We provide complete product solutions, product manuals and more wonderful contents. Please leave your message and information below