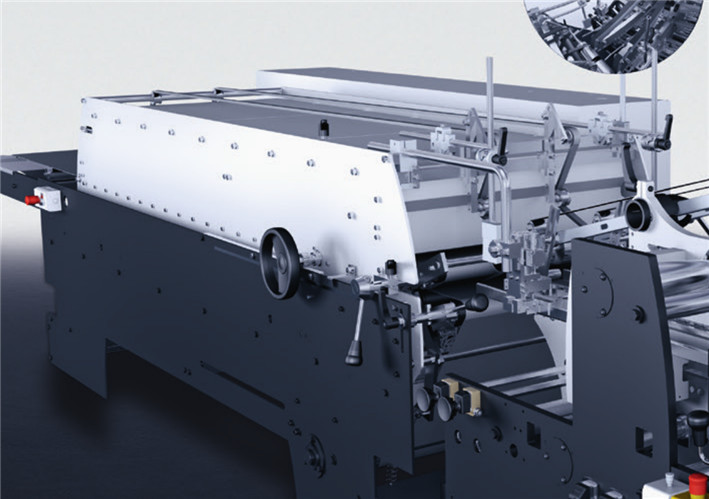

Compression and Delivery Section

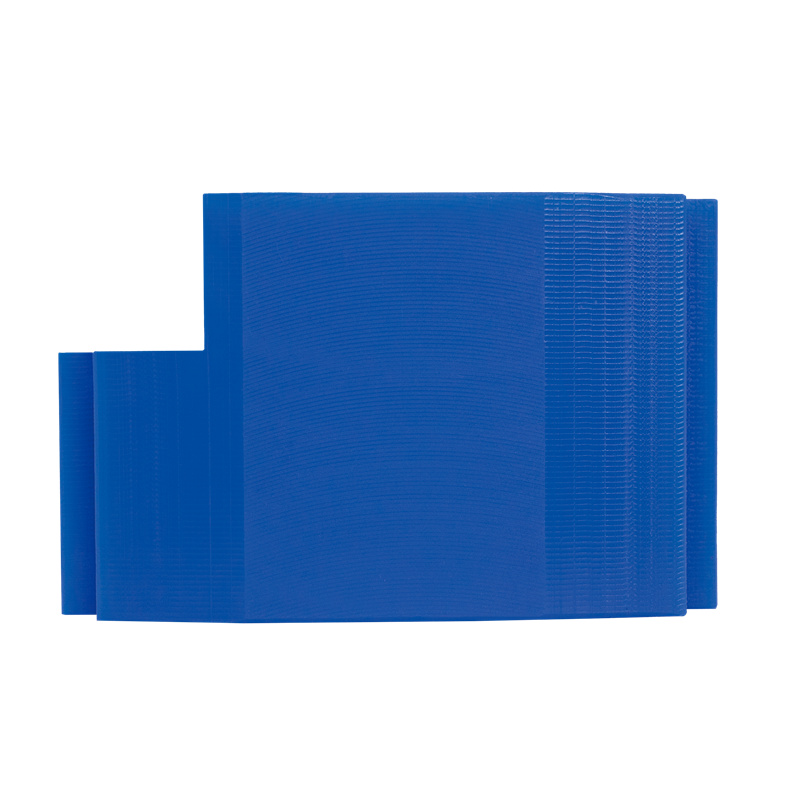

For size 55,80 and 115 A,B:

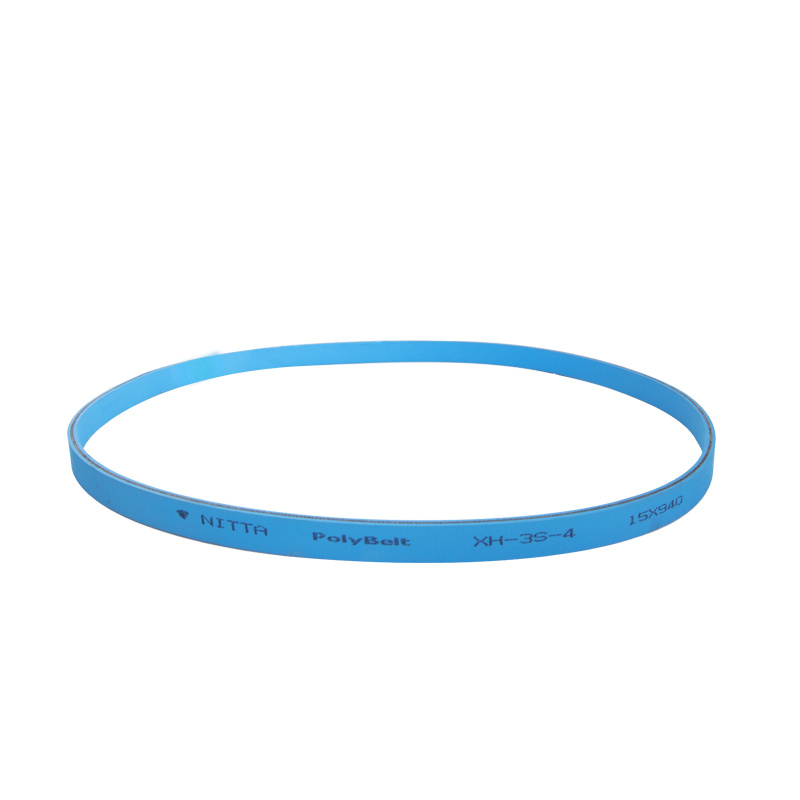

600 mm wide compression belt

2.3 m compression track

Manual setting of compression zones

Soft rubber belts for local pressure application (optional)

For size 115 C:

900 mm wide compression belt

3 m compression track

4 pressure zones with fine adjustment

Soft rubber belts for local pressure application (optional)

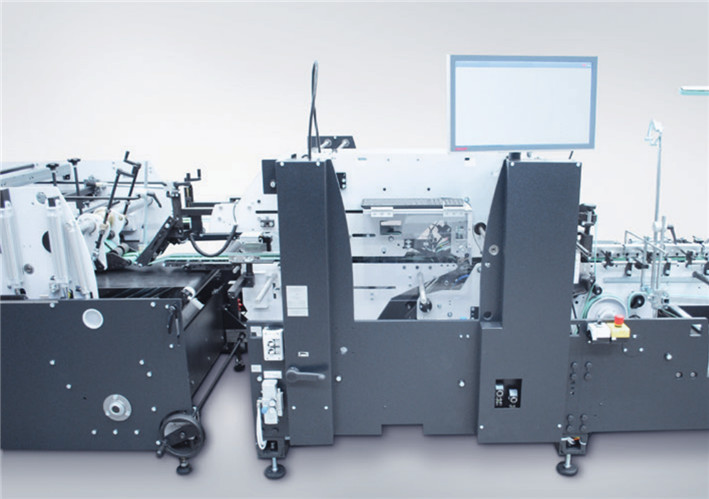

Transfer Station

Electronical speed regulation

Linear ejector (optional)

Manual longitudinal adjustment of the upper and lower carriers

Operation unit with touch-screen Transfer section with integrated linear ejector (optional):

Servo-drives ensure precise operation

Transport belts are lowered for ejection

All carton styles and sizes can be ejected at max. Speed

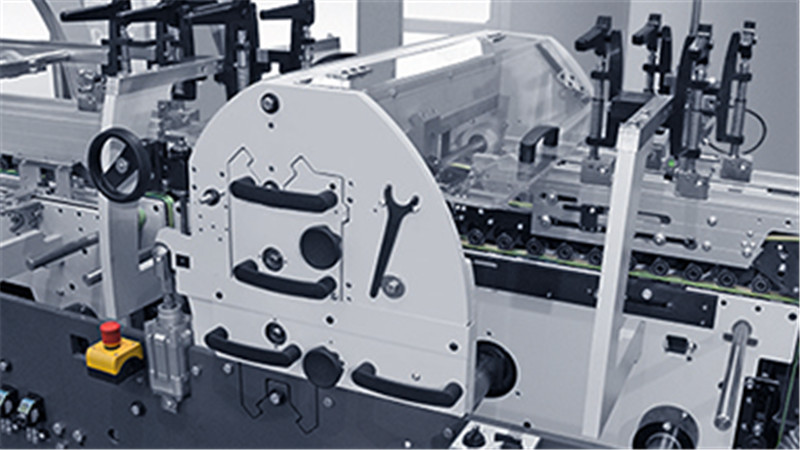

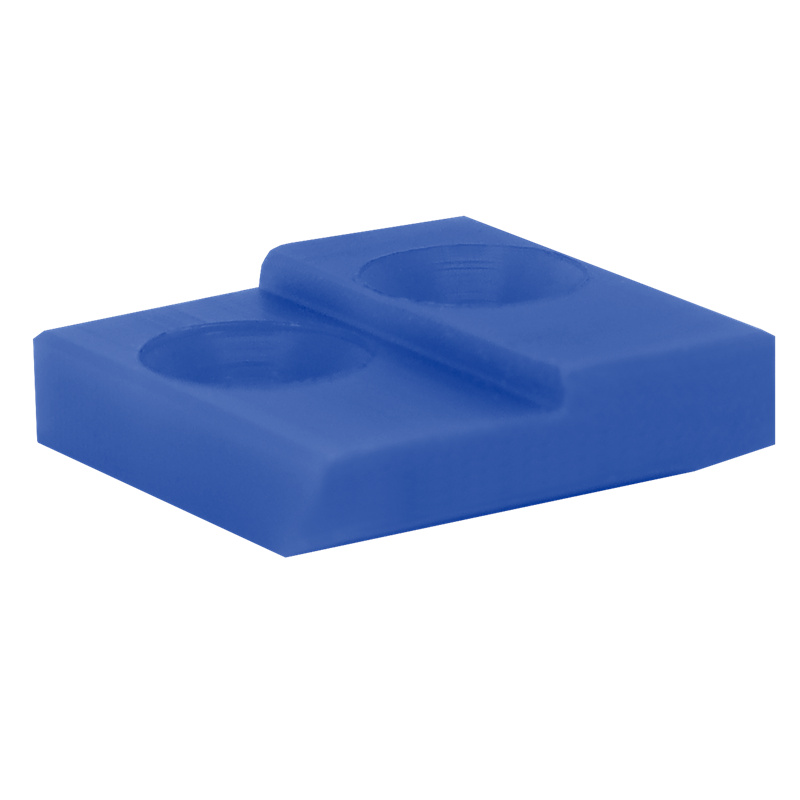

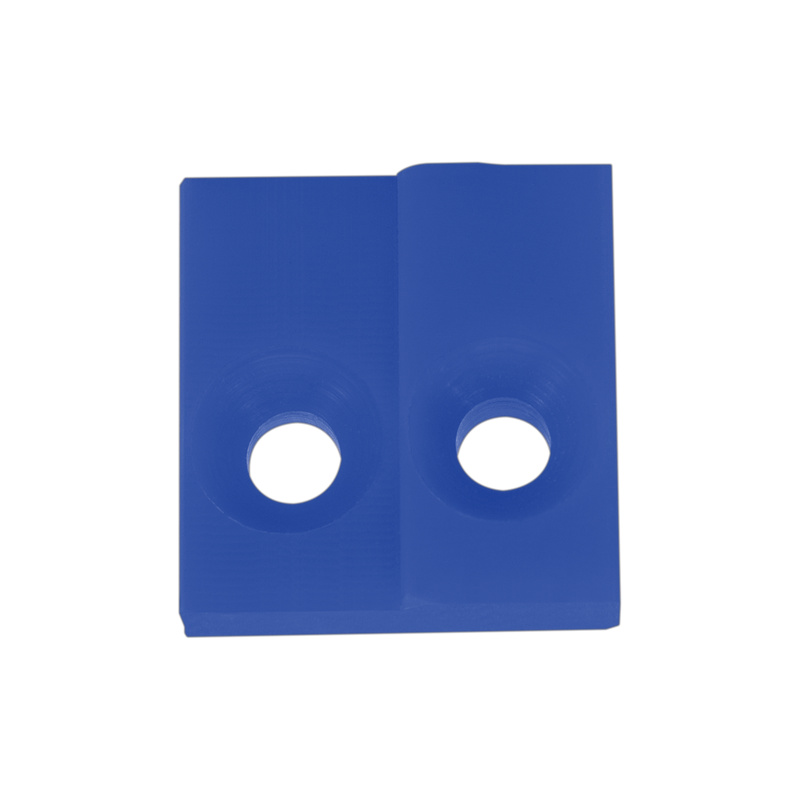

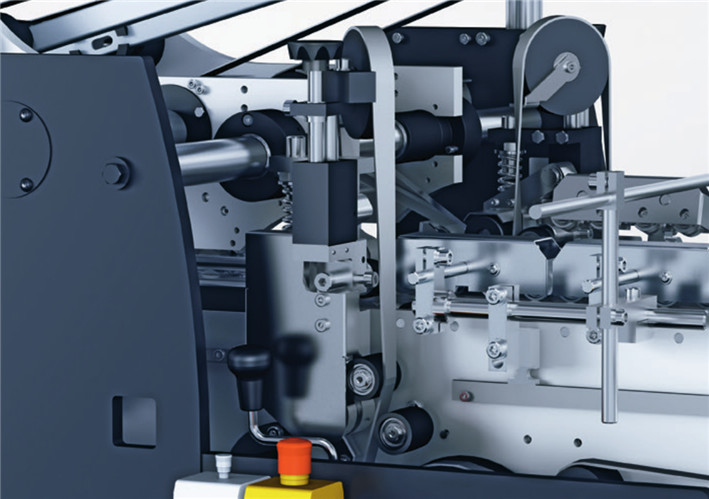

Pressing Station

Reduces the reject forces of the folded creasing

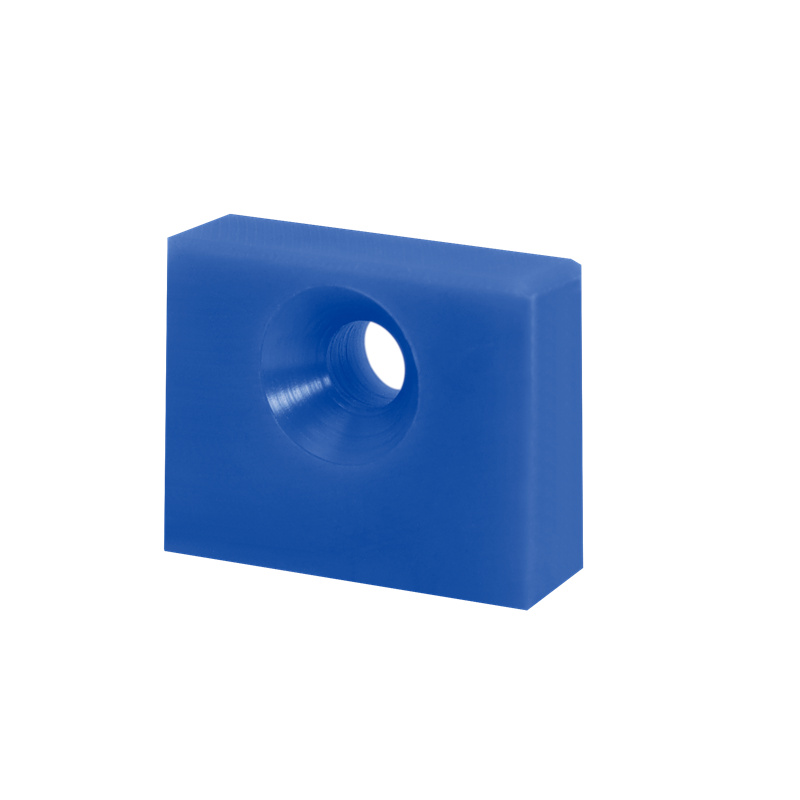

Individual pressure adjustment via ergonomically designed hand-wheels for operator and drive side

Suitable for sensitive carton surfaces

Lateral positioning together with the exterior lower carriers of the folding station

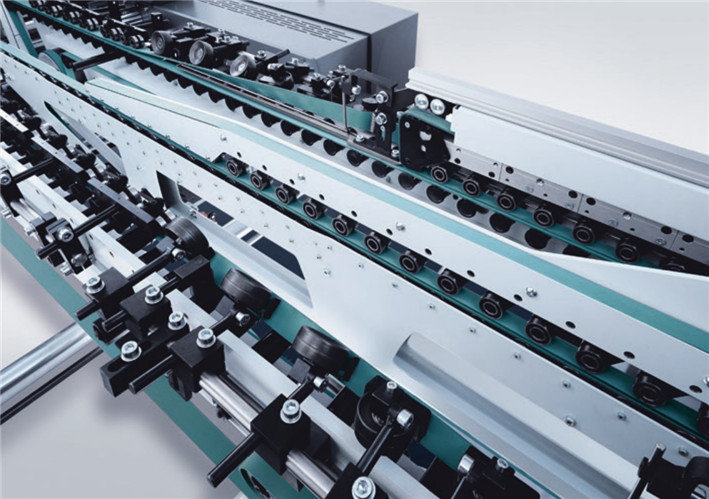

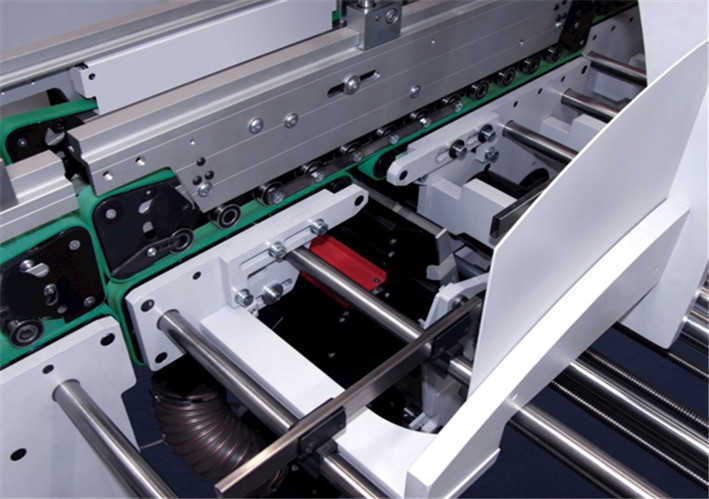

Folding Station

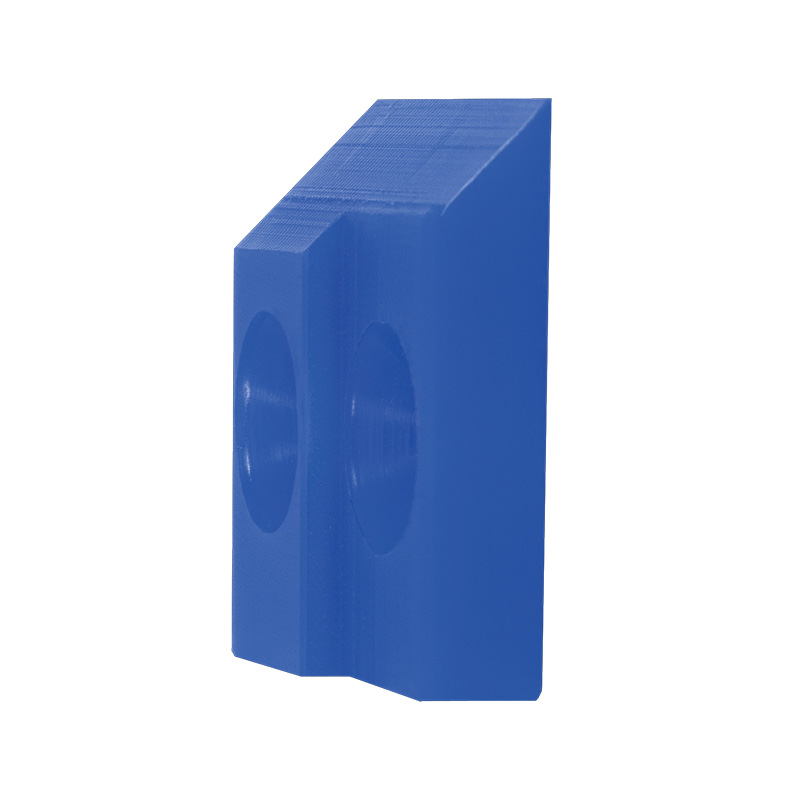

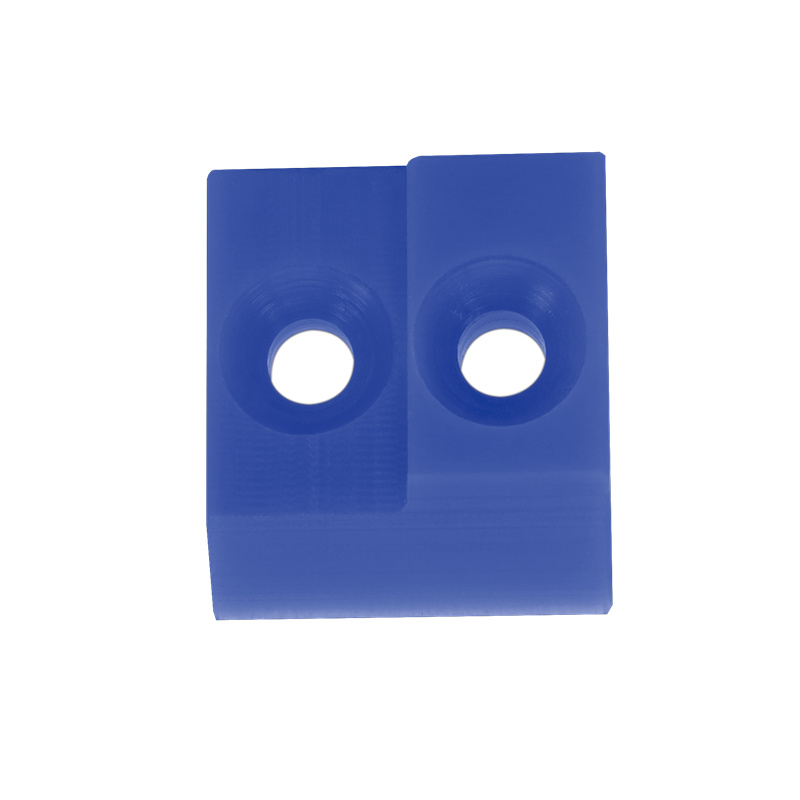

One left and right telescopic roller bar on either side which can be shifted

Left-before-right folding or right-before-left folding as standard

Lower center carrier, can be hinged downwards (optional)

Upper center carrier, can be removed or hinged upwards (optional)

Lowered side frames for excellent accessibility

Belt folding for 45 mm open carton width is possible (optional)

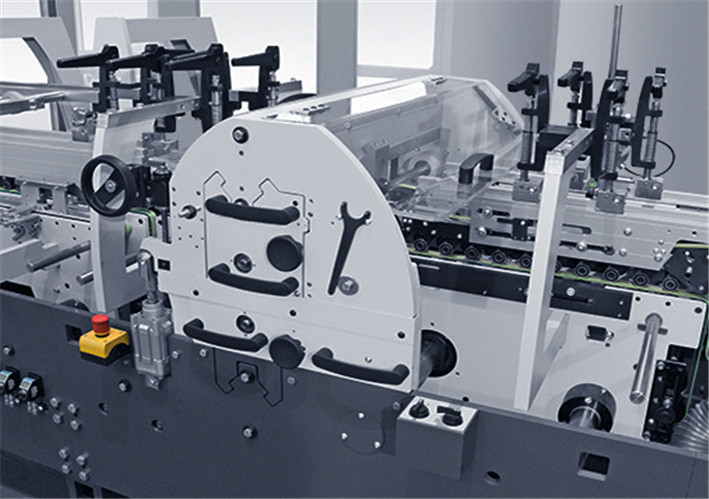

Combimodule

3 lower and 5 upper carriers

Processing 4- and 6-corner collapsible cartons

Comfortable and fast set up to process lockbottom carton

1. Backfolding shaft in the rear prefolder, 2. Backfolding shaft in the Combimodule

Safety light gates for full body protection without obstructing the make-ready

Prefolder

Excellent accessibility thanks to low side frames on operator and drive side

One lower carrier each right and left side

One upper roller bar on the right side and two upper roller bars on the left side

Short upper carrier for rear drive side available as option

Belt folding on drive side

Optional lockbottom device

Diana Braille Module

Braille tool, can be positioned across the entire working width

Several tools can be used in parallel

High productivity thanks to an optimum number of embossing areas on the embossing metal sheet

Braille tools can also be set up outside the machine

Reliable carton transportation at the embossing stage

Systemic embossing quality control

Module length shorter than 1,400 mm regardless of the number of Braille tools

Diana Inspection Control Module

100 % inline inspection of the entire print image

Inspection of defined areas with different resolutions

Setting values can be saved for repeat jobs

Comparison of read-in image with prepress PDF

Automatic ejection of defective or skew cartons is possible

Automated reporting

Reliable carton transport

Low energy consumption (blast air and LED lighting)

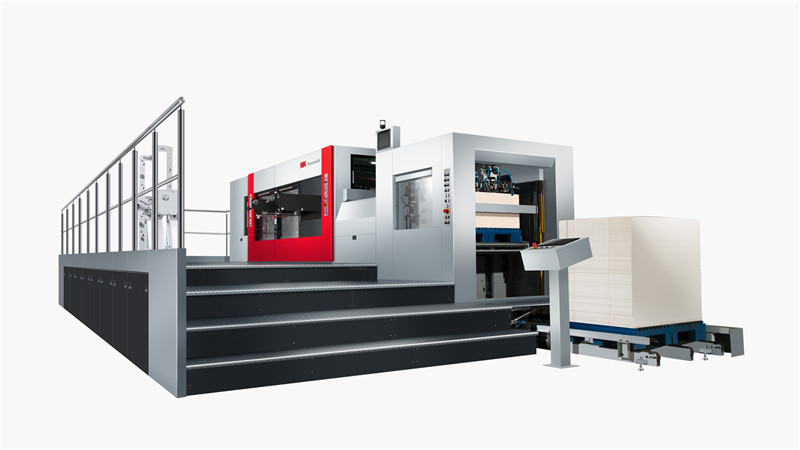

Feeder with Blank Aligning Module

Short set-up times

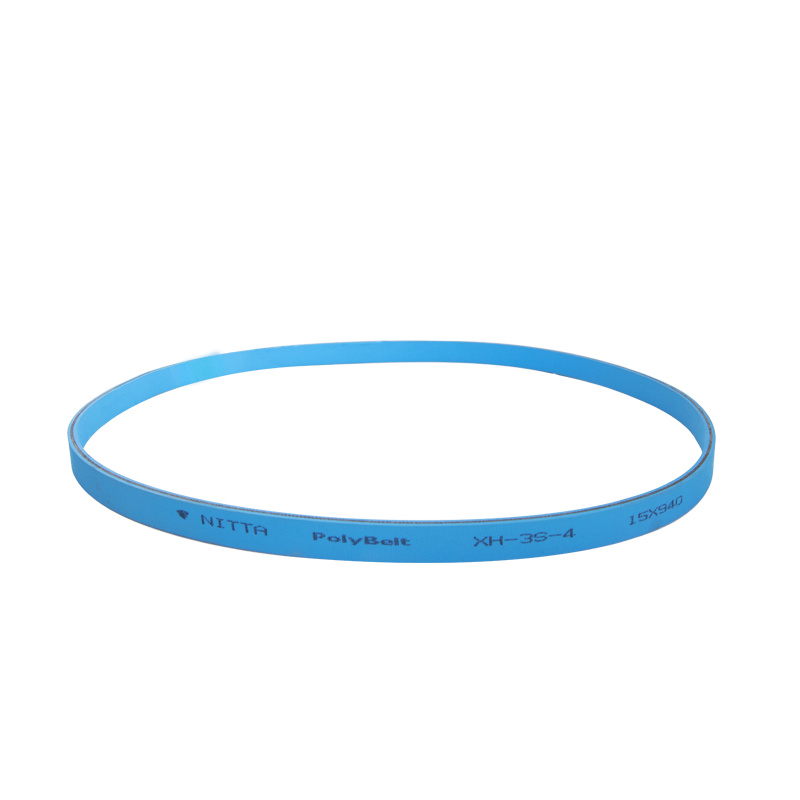

Friction feeder with adjustable belt guides

Belt replacement in less than 60 seconds without pulling a shaft

Individual drive for precise speed control

Transport carriers are adjustable in lenghts

Suction feeder (optional)

Alignment can be done either to the left or to the right

Aligning linear is adjustable sidewise in order to skip window cut-outs

Optional upper/lower center carrier

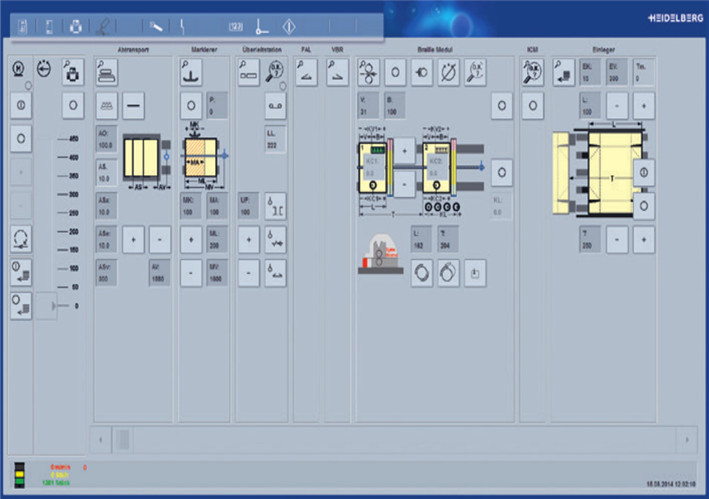

Machine Interface and Automation

Touch-screen for machine operation

Straightforward handling, self-explanatory menu navigation

SmartSet positioning, can be stored for repeat jobs (option)

DigiSet: Gives the operator the settings to position carriers based on the configuration of the blank. Settings can be stored for repeat jobs.

AutoSet:Set-up calculated based on the blank and the carriers are moved automatically into position

Camera system for monitoring the transfer station (option)

Diana Feeder

Continuous, stable pre-feeding

Constant stack height in the feeder

High production reliability

Supporting high-speed production

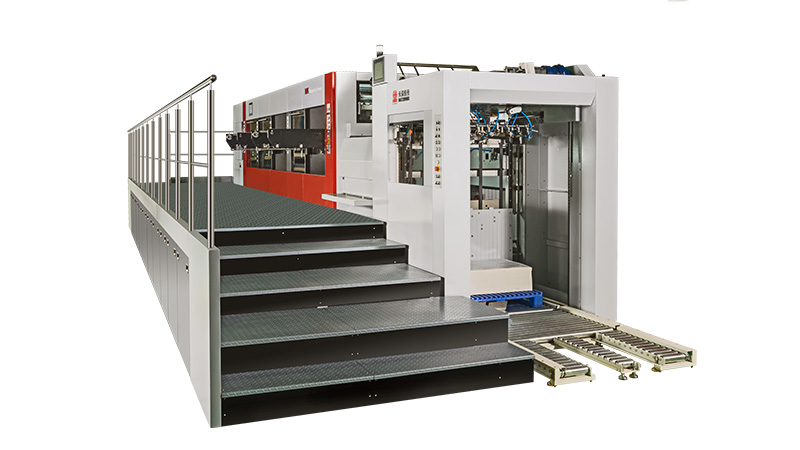

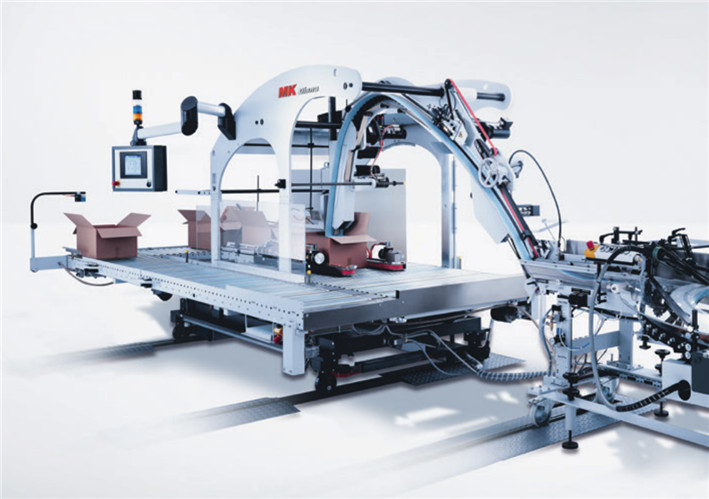

Diana Packer

Fully-automated packing into shipping cases

Packing on crease lines 2 or 4 or on closure flaps possible

Up to 5 rows per layer and up to 5 layers per case

Up to 200,000 straight-line cartons per hour

Pre-calculation of set-up data for fast make-ready

Automated Case Control available

| Max. Speed | 450 m/min |

| Material (Solid board) | 200 - 600 g/m2 |

| Material (Solid board) | N/E/F micro-currugated board |

| Min. carton width | 45 mm |

| Max. carton width | 550 mm (Diana Smart 55) 800 mm (Diana Smart 80) 1150 mm (Diana Smart 115) |

For more information, please download the PDF brochure, or click "Contact" to subscribe

Click download

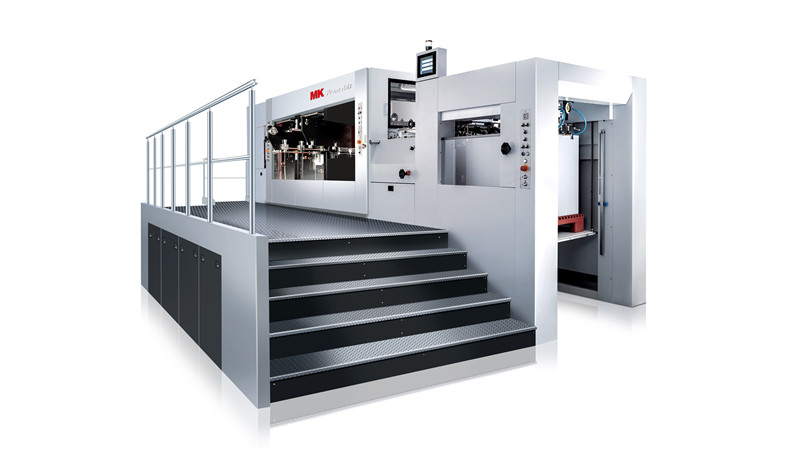

Automatic carton gluing machines

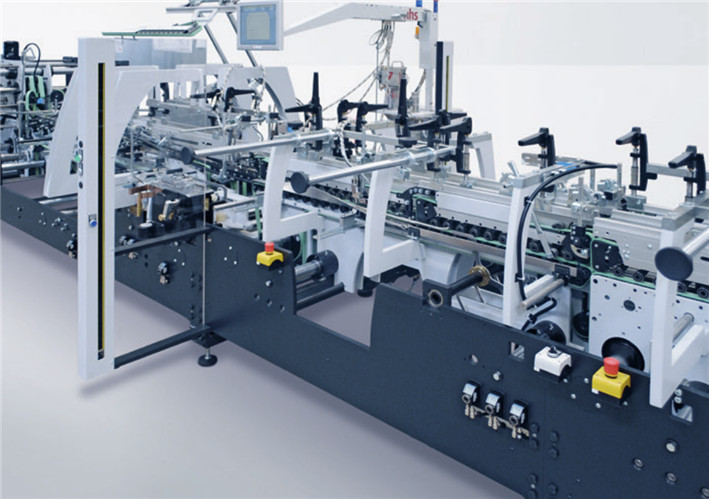

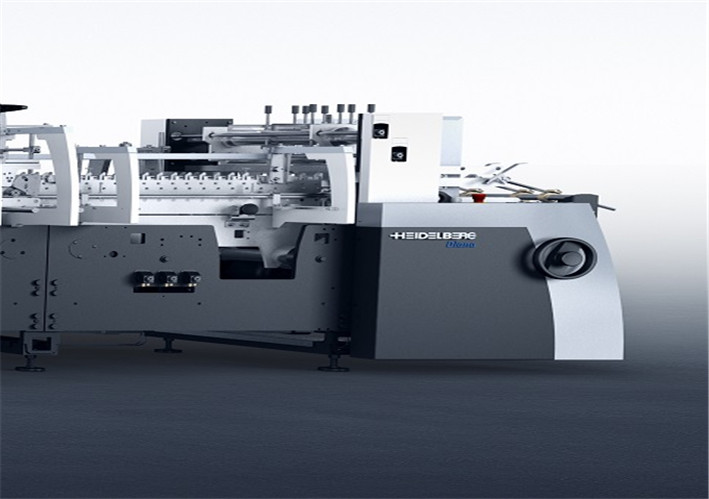

High-Speed Automatic Folder Gluer Machine

At Masterwork, we understand the ever-growing demands of the packaging industry, and our high-speed automatic folder gluer machine is designed to meet those needs. Engineered for rapid production, this machine can handle a variety of materials, including paperboard and corrugated sheets, making it an essential tool for businesses seeking to optimize their packaging processes. With speeds of up to 450 meters per minute, our machine significantly increases throughput without compromising quality, ensuring your production line runs smoothly and efficiently.

Automatic Folder Gluer Machine with Quality Control System

Quality is paramount in packaging, and that’s why our automatic folder gluer machine comes equipped with an advanced quality control system. This integrated feature allows for real-time monitoring of the gluing process, ensuring that each box meets the highest standards of precision and reliability. The system automatically adjusts glue application based on the material thickness and type, preventing wastage and ensuring consistent quality throughout the production run. With our machine, you can confidently produce packaging that not only looks great but also performs flawlessly, safeguarding your products during transport and storage.

Automatic Folder Gluer Machine Maintenance and Troubleshooting

To maximize the performance and longevity of your automatic folder gluer machine, regular maintenance is crucial. At Masterwork, we provide comprehensive support, including detailed maintenance guides and troubleshooting tips to keep your machine running at peak efficiency. Our user-friendly manuals cover essential maintenance tasks such as lubrication, part inspections, and cleaning protocols, making it easy for your team to ensure the machine is always in top condition.

In the unlikely event that you encounter issues, our troubleshooting resources are readily available. We offer step-by-step instructions to identify common problems and provide solutions, minimizing downtime and keeping your production line on schedule. Our dedicated support team is also just a call away, ready to assist with any inquiries or technical issues that may arise.

Investing in Masterwork’s high-speed automatic folder gluer machine means choosing reliability, efficiency, and quality. With our advanced features and unwavering support, you can elevate your packaging operations and stay ahead of the competition. Visit Masterwork today to learn more about how our innovative solutions can transform your packaging processes and drive your business forward.

+

Related Products

Question consultation message

We provide complete product solutions, product manuals and more wonderful contents. Please leave your message and information below