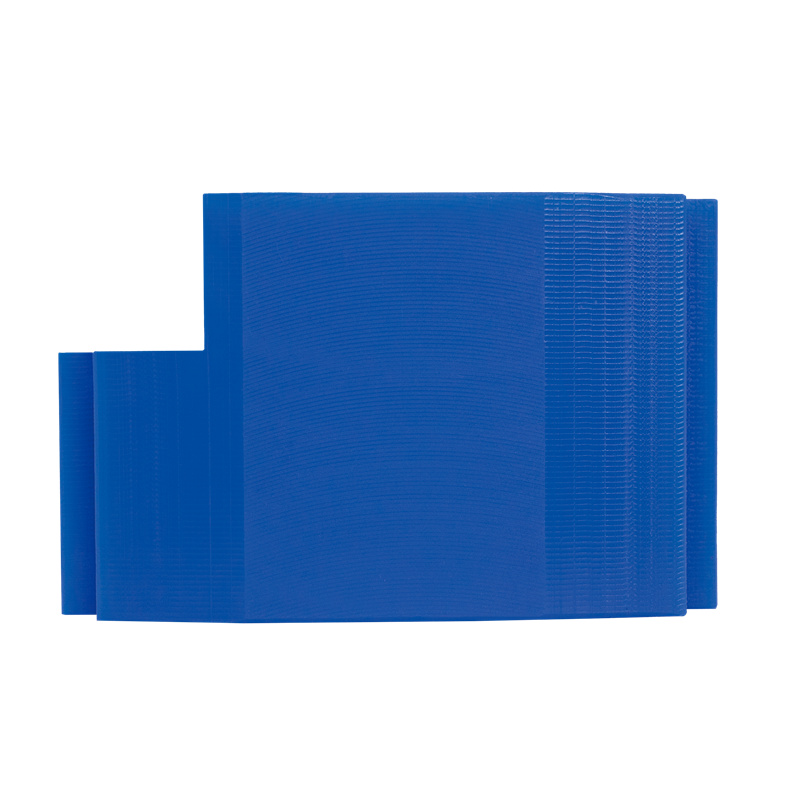

Mechanical Part

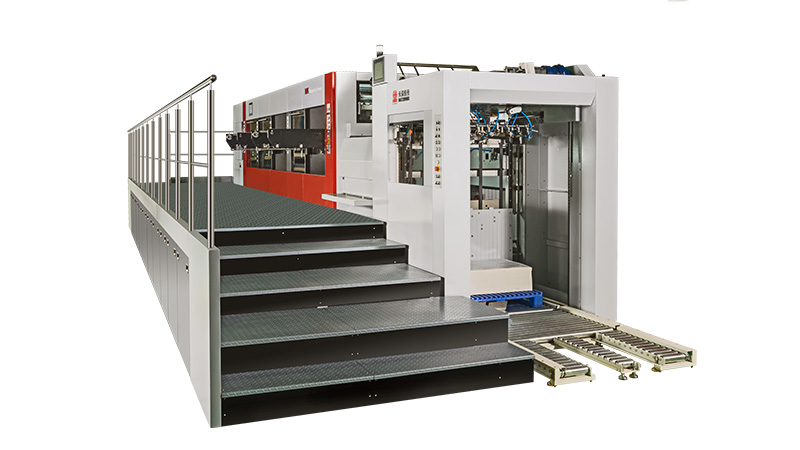

Rolling feeding platform

Using imported deviation correcting device

Automatic tension control to ensure more stable and reliable tape running.

Equipped with laminating, slitting, waste discharging function

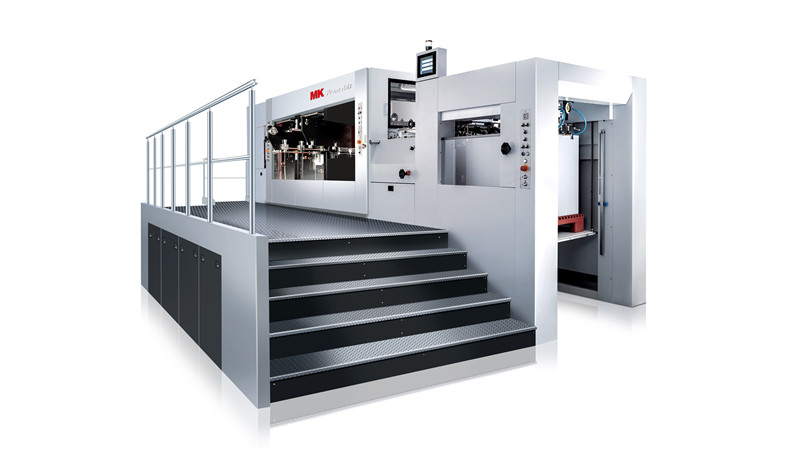

Optical Part

Using advanced metal tube laser with stable performance, convenient and concise control

Three-dimensional dynamic focusing mode, uniform light path, processing area is large.

Using the 650nm visible light, it helps to align and adjust the optical path much quicker.(Optional)

Electrical and Control Part

Encoder is adopted to feed back movement information

High precision color code monitoring system ensures cutting accuracy

Software with simple and friendly interface, easy operations on the image position, laser power and other control actions.

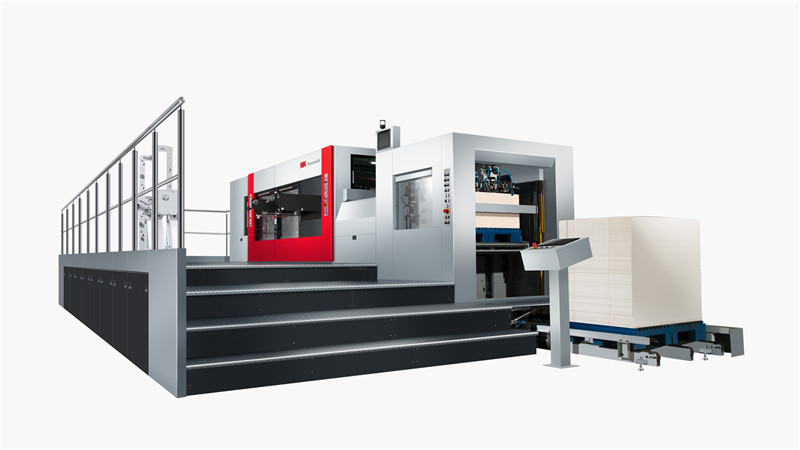

| Technical Specifications : | LC 330RE |

| Design Type: | Roll to Roll |

| Max. Sheet Size: | 330mm |

| Application Materials: | Self-Adhesive Paper |

| Light Source: | CO₂ |

| Laser energy: | 180W |

| Positioning Method: | Color Code Sensor+Auto Deviation Correction |

| Max. Scan Range: | 320mm |

| Input File: | PLT,DXF |

| Power Supply: | AC380V 50Hz 5-8KW |

| Working Environment: | (T25±2°C, RH40%-60%) |

| Net Weight: | 1200KG |

| Machine Dimension: | 3360X2220X1690mm |

| Optional: | Online Sheeter |

For more information, please download the PDF brochure, or click "Contact" to subscribe

Click download

Related Products

Question consultation message

We provide complete product solutions, product manuals and more wonderful contents. Please leave your message and information below