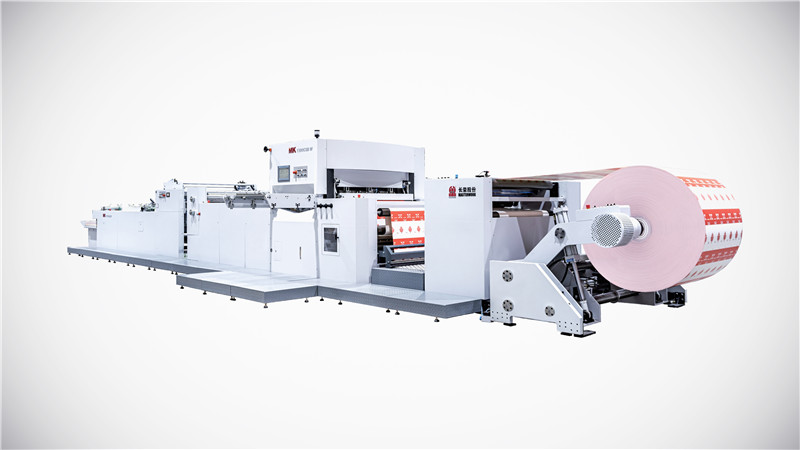

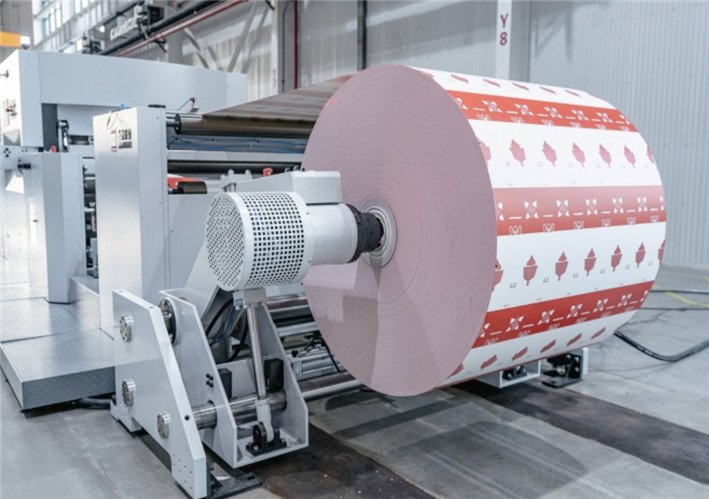

Unwinder unit

Laser light pre-positioning function when changing rolls

Reel change hydraulic system control

Maximum unwinding diameter 1600 mm

Paper splicing platform, easy to change roll operation

The unwinding chuck adopts the tightening method

Automatically detect and calculate the roll diameter, and alarm when the paper roll is in over use

Paper infeed unit

Paper positioning in electronic front lay

Electronic front lay is detected by three-color code detection sensor

Imported high-end deviation correction system, which can realize switching between line correction and edge correction

Adopt enterer to drive paper feeding, realize dynamic correction, and ensure the accuracy of paper feeding

Servo motor driven in paper feed swing arm type has been adopted, and the cylinder is driven by air to realize the intermittent test delivery inside the molding unit

Equipped with paper folding and flattening mechanism

Equipped with tonnage detection,overpressure alarm device, etc.

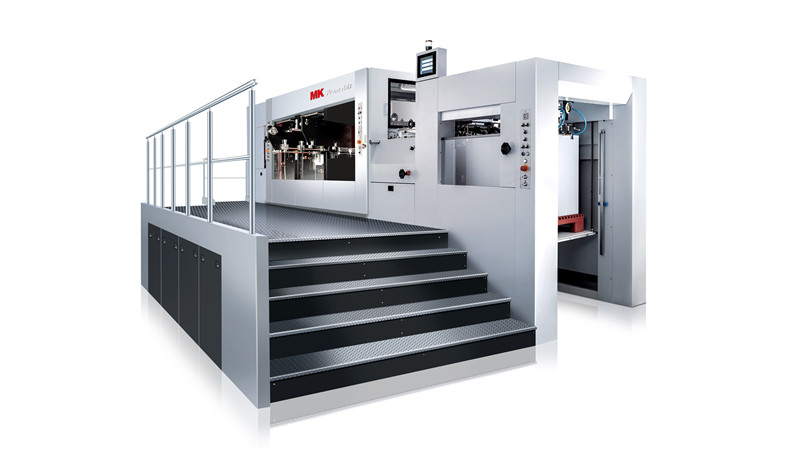

Die cutting main unit

Optimized design of moving platform and pressure adjustment device

Electric pressure regulating mechanism

Pneumatic lock chase mechanism

Synchronous fine-tuning mechanism for the lower plate of the chase frame

Paper transfering unit

Separating die-cut webs into individual sheets

Paper kicking, belt positioning is fast, and the waste removal rollers are all driven by enterers

The kicking angle is automatically set, and the operation is simple and convenient

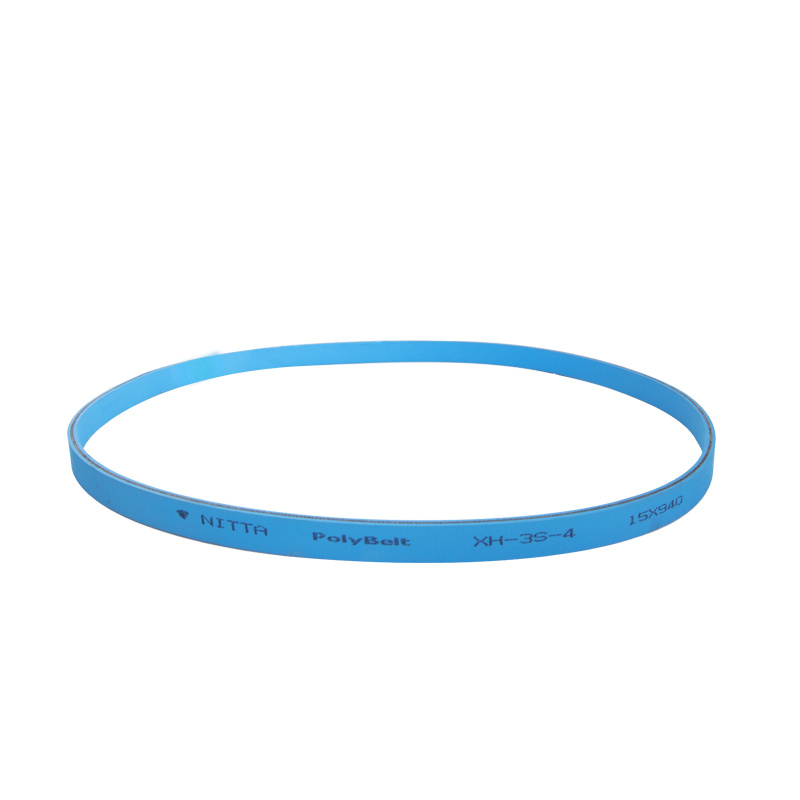

The conveying belt of the paper conveying table adopts the configuration rules on the synchronous belt, and the separated paper is pre-positioned.

Stripping unit

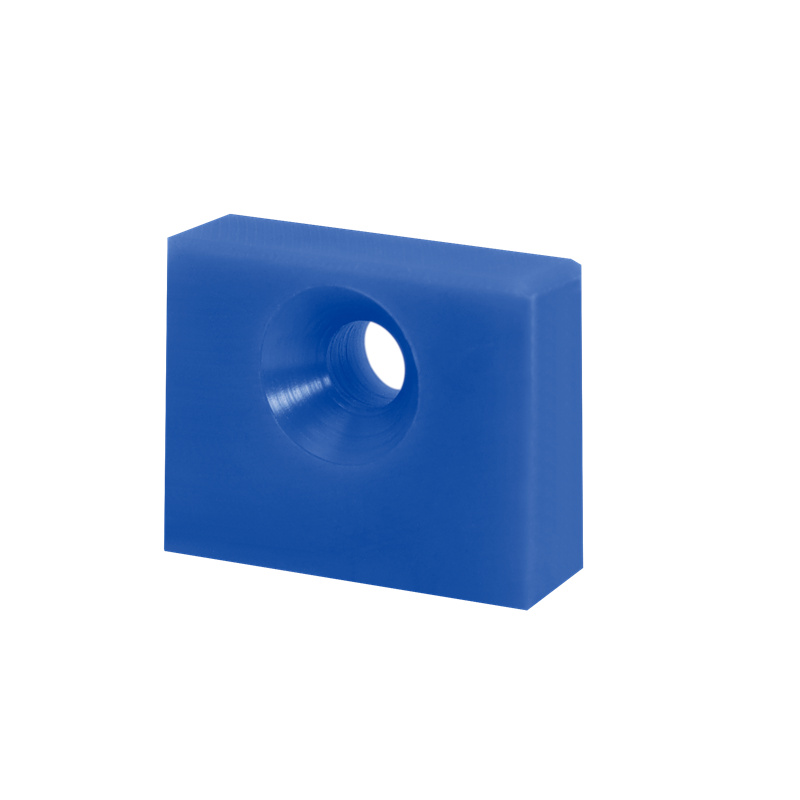

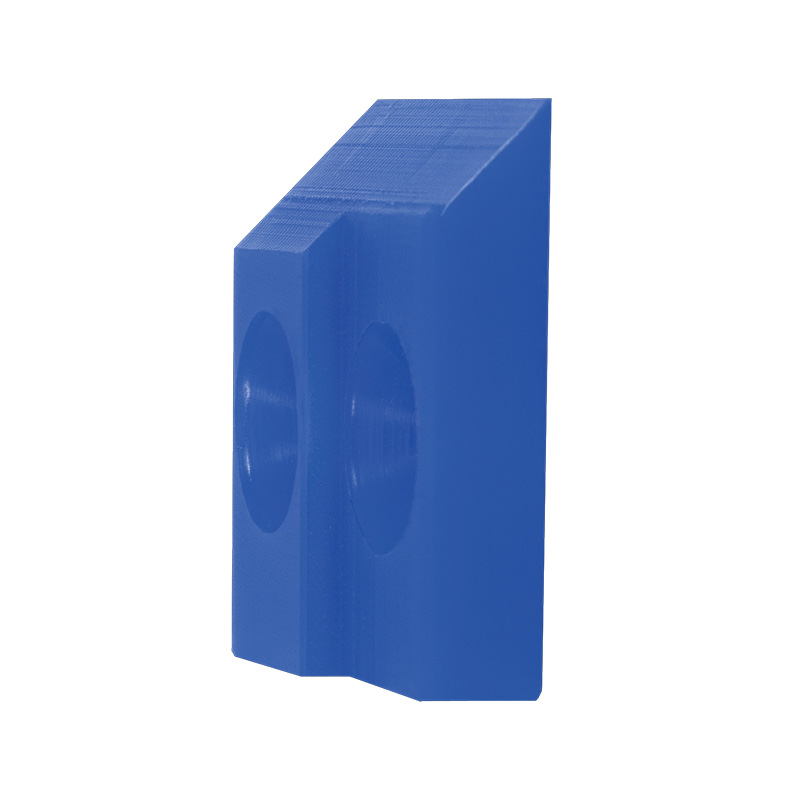

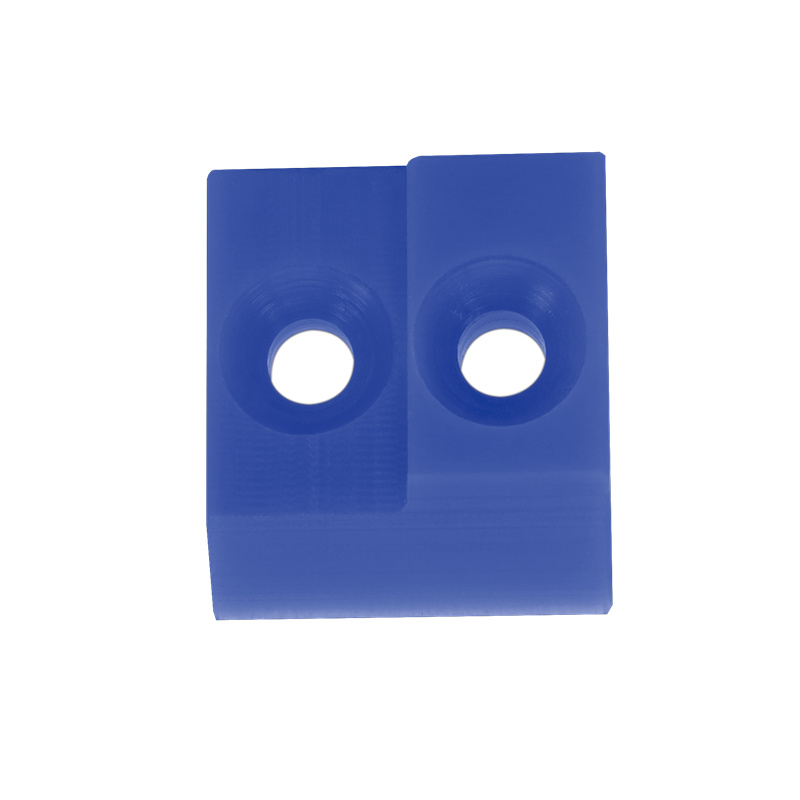

The roller type stripping device only needs to install the cleaning needle on the roller, which is simple and convenient to install, does not require the cleaning plate, and saves the cost of plate cleaning cost

The paper feed vertical and horizontal direction can be adjusted

Equipped with a waste edge conveyor belt device to transport the cleaned waste edge out of the machine (waste collection or fan ducts are determined by the customer's factory facilities)

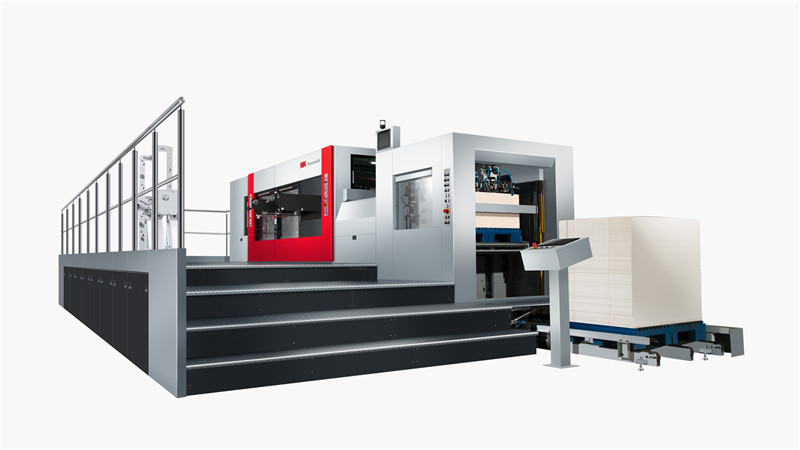

Separation unit

Independent upper and lower belt separation device

Pneumatic lifting device for separating upper pressing belt

The overall angle of the upper and lower belt pressing device is adjusted to realize the height adjustment of the paper outlet, so as to adapt to the collection of different products

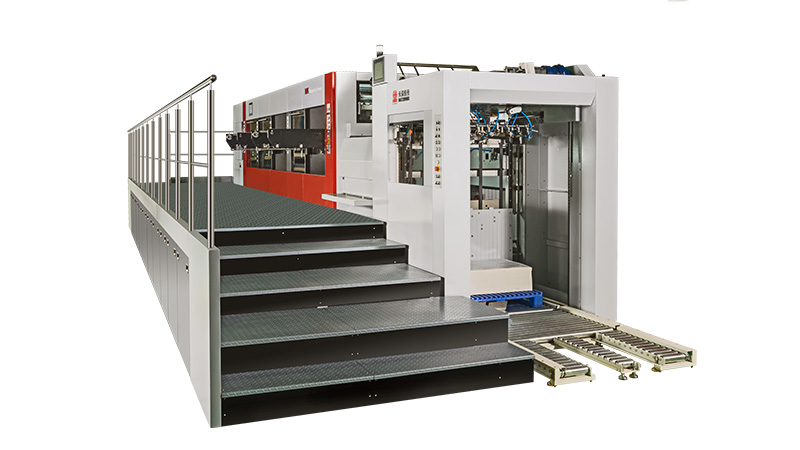

Delivery unit

Fish scale device

Automatic stacking device (this is an option, including the following functions)

Automatic counting separation device

Pneumatic jogging device

Automatic lifting and output of finished paper stacks

Stripping tolling

Equipped with punching tooling for stripping needle of waste cleaning lower drum

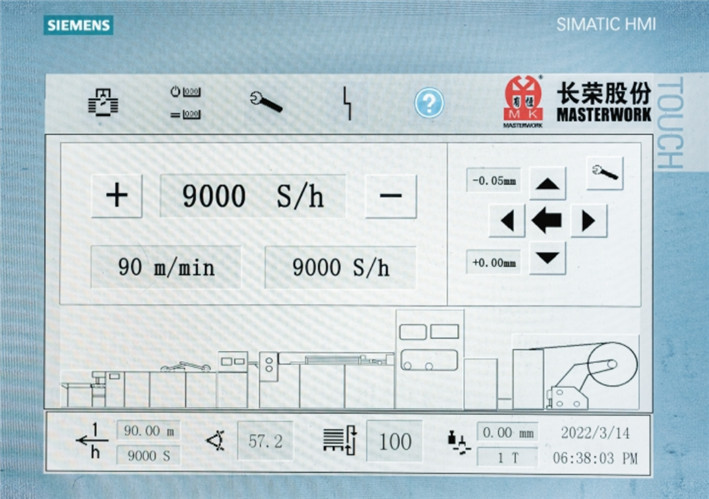

HMI

Hign definition touch screen and control system

Humanized graphic control interface makes the control of the whole machine more vivid, convenient and flexible

Siemens control system

Multi-pump linkage control system with independent intellectual property rights

Multiple mechanisms are controlled by independent motors

Proprietary color mark positioning control program

Equipped with imported motion controller

| Technical parameters | Intelligent MK1300CSB W |

| Web size | 180-500 g/m2 |

| Web width | 600-1300 mm |

| Paper length | 450-945 mm |

| Maximum path of the web | 1600 mm |

| Maximum line speed | 90 m/min |

| Host maximum frequency | ≤9000 s/h |

| Maximum die-cutting width | 1300 mmx945 mm |

| Minimum die-cutting width | 600 mm*450 mm |

| Repeat overprint accuracy | ≤±0.2 mm |

| Maximum working pressure | 250 ton |

For more information, please download the PDF brochure, or click "Contact" to subscribe

Click download

Related Products

Question consultation message

We provide complete product solutions, product manuals and more wonderful contents. Please leave your message and information below