In the postpress segment of the packaging and printing industry, automatic die cutting machines are among the most critical assets influencing production capacity, yield, and delivery reliability. A truly reliable supplier must offer more than individual machine models—it must deliver a systematic combination of equipment performance, automation capability, changeover efficiency, global delivery capacity, and lifecycle service support.

The value of Masterwork (MK) lies precisely in its integrated “product + technology + service” capabilities. From large-format corrugated solutions to high-end folding carton applications, from high-capacity intelligent production to innovative dual-station configurations, and extending to installation and commissioning, spare parts support, training, and remote assistance, MK delivers end-to-end solutions that are practical, reliable, and ready for implementation.

Masterwork’s automatic die-cutting product portfolio is designed to match different business models with the appropriate machine configurations, effectively covering the two primary battlegrounds of the market: large-format corrugated applications and high-value folding carton paperboard (solid board).

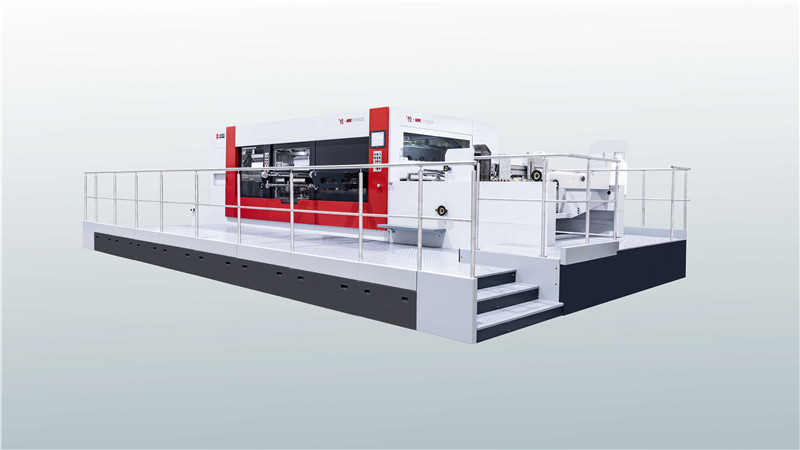

Designed for large-format corrugated and laminated board production, the MK Ecocut 170CS features a flatbed automatic die cutting system with in-line stripping. It supports corrugated and laminated substrates with a thickness range of 1–8.5 mm and delivers a maximum output of approximately 6,000 sheets per hour.

Key productivity-enhancing features include center positioning systems and quick-lock die chases, which significantly reduce makeready and changeover time. For plants handling multi-up layouts, mixed specifications, and tight delivery schedules, this model delivers measurable improvements in effective output per shift.

The MK Ecocut 130CS addresses common mid-to-large format corrugated requirements with a focus on efficient stripping, waste removal, and quick die change systems. With a maximum speed of approximately 6,000 sheets per hour, it provides an excellent balance between footprint, energy consumption, and application versatility.

For converters seeking a cost-effective solution that integrates smoothly into existing production lines, this model offers a fast return on investment through stable performance and high machine utilization.

Built on the industry-standard 1060 format, the Mastermatrix 106CSB is positioned as a high-end automatic die cutter for solid board applications. It delivers a maximum speed of up to 9,000 sheets per hour, with a maximum sheet size of 1060 × 760 mm and a maximum die cutting area of 1060 × 745 mm.

Beyond speed, this platform emphasizes registration stability, consistent creasing quality, and downstream folder-gluer compatibility, making it well suited for demanding packaging sectors such as food, cosmetics, and pharmaceuticals.

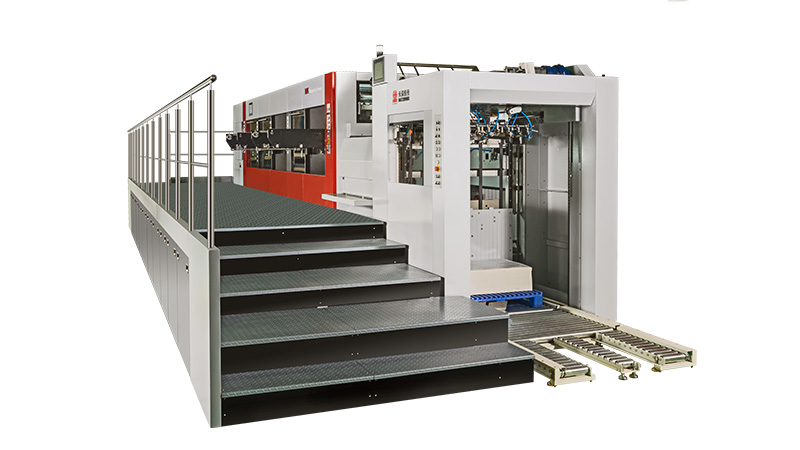

The Duopress Power 106CSB stands out with its dual-station configuration combined with an integrated blanking system. Described as a globally patented innovation, it achieves up to 7,000 cycles per hour and supports board weights ranging from 90 to 2,000 g/m².

By enabling blanking directly within the die cutting process, this model reduces secondary operations, manual handling, and labor costs—delivering tangible improvements in overall equipment effectiveness (OEE) for high-volume, efficiency-driven operations.

Choosing an automatic die-cutting machine is, in essence, choosing a long-term partner. Masterwork’s core strengths are built on decades of industrialization and a well-established R&D ecosystem:

Foundation and capitalization: Founded in 1995 and listed on the Shenzhen GEM in 2011.

Scale and product portfolio: With more than 1,600 employees, Masterwork offers multiple product lines and series, providing a systematic range of equipment solutions for the packaging and printing finishing sector.

Global market reach: Products are sold in over 80 countries, supported by proven cross-regional delivery and service capabilities.

R&D investment and technical centers: Masterwork operates a nationally recognized technology center with over 200 professionals and consistently invests approximately 5%–7% of annual revenue into research and development.

International collaboration and channel strength: Since 2015, MK-branded products have been globally distributed by HDM. In 2019, Masterwork became HDM’s largest shareholder, establishing a strategic partnership that further strengthened global market access and collaboration.

These capabilities ensure that Masterwork machines are not only delivered and installed, but also supported, upgraded, and serviced reliably over their entire lifecycle.

For high-value capital equipment such as automatic die cutters, service capability directly impacts real-world uptime. Masterwork’s service system spans installation, operation, and long-term optimization.

The installation, space optimization, and operational ramp-up after equipment arrives on site are critical to a smooth start-up phase. Masterwork emphasizes installation and relocation services delivered by professional after-sales teams to ensure that equipment is properly commissioned once it reaches the customer’s facility.

On the production floor, restoring the line quickly is often more important than identifying the root cause. Masterwork provides dedicated troubleshooting support, underpinned by deep expertise in its own equipment and the ability to deliver effective, practical solutions.

Spare parts availability directly impacts downtime costs. Masterwork highlights its ERP-driven supply and warehouse management system, which enables reliable replenishment. Standard parts benefit from fast quotation and dispatch, with relatively short delivery lead times achievable in most major and mid-sized cities.

The service scope includes maintenance manuals, periodic maintenance recommendations, and, when necessary, on-site guidance and support, ensuring that equipment operates at optimal performance over the long term.

For automatic die-cutting operations, training has a direct impact on job changeover efficiency, yield, and safety. Masterwork notes that its training center and dedicated training department were established in 2011. To date, more than 300 training sessions have been completed, reaching over 1,500 participants. The program offers eight categories of training and more than 40 courses, covering operation, process optimization, commissioning, and maintenance.

For converters aiming to transform die cutting from a single machine operation into a repeatable, scalable production system, Masterwork offers a compelling value proposition:

MK Ecocut 170CS and 130CS for corrugated and laminated board applications emphasizing stripping and fast makeready

Mastermatrix 106CSB for high-end folding cartons requiring high speed and consistent quality

Duopress Power 106CSB for customers seeking differentiated efficiency through dual-station blanking

A full-lifecycle service ecosystem ensuring sustained equipment performance and long-term value

Masterwork’s approach reflects a clear philosophy: true productivity gains come from stability, system integration, and long-term partnership—not speed alone.

Products

Contact us

Related Information

Content

We look forward to hearing from you. In order to respond to your message more quickly, we need some information. *These are required